Flow dividers

Flow dividers MTDA

Flow dividers MTDA

Bucher

Product code: 2373

M18x1.5, M22x1.5, M27x2, M33x2

G3/8–G1

maximum working pressure: 315 bar

maximum flow rate: 250 l/min

flow division error: ± 3%

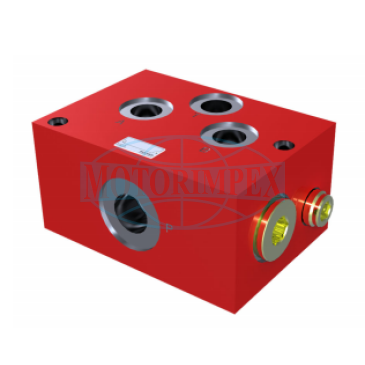

Flow dividers MTDA-HD

Flow dividers MTDA-HD

Bucher

Product code: 2374

G1/2, G3/4, G1

maximum working pressure: 420 bar

maximum flow rate: 250 l/min

flow division error: ± 3%

Flow dividers MTDA08HG

Flow dividers MTDA08HG

Bucher

Product code: 2372

G3/8

maximum working pressure: 315 bar

maximum flow rate: 50 l/min

flow division error: ± 1.5 %

Flow dividers QXT

Flow dividers QXT

Bucher

Product code: 2375

maximum working pressure: 250 bar

maximum flow rate: 2000 l/min

maximum working capacity: 250 cm3/rev

flow division error: ± 2%

Flow dividers FD2WP

Flow dividers FD2WP

Hypress

Product code: 5015

G3/8, G1/2

maximum working pressure: 300 bar

maximum flow rate: 80 l/min

flow division error: ± 2 %

Hydraulic flow divider

Hydraulic flow divider – this is a device that allows you to distribute the flow of the working fluid evenly over two or more channels, regardless of what input load is applied to the hydraulic actuator.

Flow dividers are used in hydraulic systems where there is a need to synchronize the movement of several hydraulic motors and hydraulic cylinders. Thanks to this, the flow is precisely distributed in hydrostatic support systems and others.

Types of flow dividers

According to the design features, the oil flow divider is divided into types:

- Spool (throttle). They consist of a body, including one inlet and two outlets, as well as a spool. Depending on the output load, the spool moves and redistributes the flow. It is necessary to choose such a hydraulic flow divider & nbsp; according to the flow range (indicated in the characteristics). There is an error of up to 3%. During installation, it must be installed horizontally. This will prevent the impact of the weight of the parts during operation of the device.

- Gear. They consist of several sections and buildings, inside which – external and internal gears. They are rigidly interconnected by a common shaft and rotate synchronously during the supply of working fluid. As a rule, such a divider is assembled into a block from two to eight sections. Also, additional pressure valves, anti-cavitation, check valves or with electric control for a common line or a separate section can be built into the design.

- Radial piston. They are similar to gears in operation, but have differences in design. Their section consists of a radial piston group, the principle of which can be compared with the operation of a hydraulic motor. Thanks to this type of divider, not only high division accuracy is achieved – up to 99%, but also wide range of working volumes. It provides a flow on a specific section up to 500l/min in some cases.

If you need to buy a flow divider for hydraulic – welcome to our catalog! We offer the most reasonable prices in Ukraine and guarantee a high level of service.