Hydraulic motors

Gear hydraulic motors QXM42-HS

Gear hydraulic motors QXM42-HS

Bucher

Product code: 4949

maximum torque: 88 N∙m

maximum speed: 10500 rpm

maximum power: 65 kW

maximum displacement: 32.3 cm3/rev

maximum working pressure: 240 bar

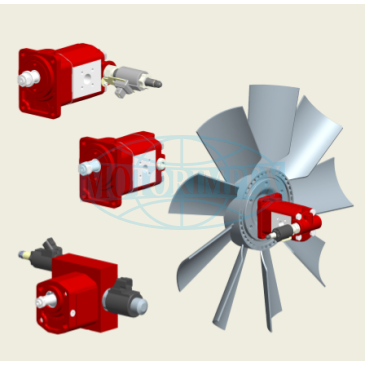

Gear hydraulic motors 1SM, 2SM and 3GM

Gear hydraulic motors 1SM, 2SM and 3GM

Galtech

Product code: 5130

maximum torque: 190 N∙m

maximum speed: 4000 rpm

maximum displacement: 77.2 cm3/rev

maximum working pressure: 280 bar

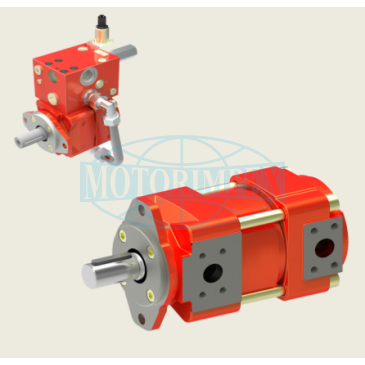

Gear hydraulic motors APM212

Gear hydraulic motors APM212

Bucher

Product code: 4951

maximum torque: 80 N∙m

maximum speed: 4000 rpm

maximum power: 24 kW

maximum displacement: 27 cm3/rev

maximum working pressure: 250 bar

Gear hydraulic motors QXM in explosion-proof version (ATEX)

Gear hydraulic motors QXM in explosion-proof version (ATEX)

Bucher

Product code: 4950

maximum torque: 1267 N∙m

maximum speed: 6000 rpm

maximum displacement: 500 cm3/rev

maximum working pressure: 320 bar

Hydraulic motors

Hydraulic motors are designed to give the output link rotational motion at an unlimited angle. Which means that working fluid under pressure is supplied to the motor inlet, as a result at the output from the shaft, the torque is removed.

Unlike electric motors, a hydraulic motor of the same power has smaller dimensions, there are more opportunities to adjust the rotation speed, and the start-up and acceleration times are only a few seconds. Such motors are not afraid of frequent on and off, as well as reverse.

Classifications of hydraulic motors:

Today, the most popular hydraulic motors are:

- axial piston (adjustable and unregulated): working body — pistons from which chambers are formed. The pistons themselves are located on a special inclined disk, the presence of which allows you to change some parameters of the motor itself (for example, rotation speed);

- radial piston (multi-speed, adjustable, unregulated): as in the previous type of motors, the executive body is pistons. Each of them is located in a separate chamber, and the working fluid is supplied to each separately. The pistons themselves are connected to the motor shaft, to which the torque is transmitted;

- gear: is both a motor and a pump. The working chambers in this device form special gears. The device requires constant monitoring of the level of the working fluid and its temperature;

- gerotor: occupy an intermediate place between axial-piston and radial-piston. They provide consistently high torque, can be used in open and closed systems. An executive body is a pumping unit, a gerotor pair. In appearance, it resembles a gear, the internal teeth of which are connected to the body of the hydraulic motor. The external gear is connected to the output shaft.

Motorimpex company offers to buy any hydraulic motor of listed. We guarantee high quality, safety and best prices.