Hydraulic cylinders

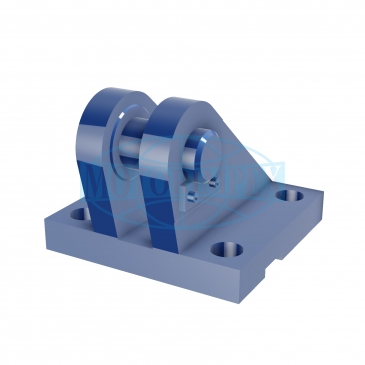

Hydraulic cylinders UCJ6

Hydraulic cylinders UCJ6

Ponar

Product code: 731

Maximum characteristics:

piston diameter: 160 mm

piston rod diameter: 90 mm

working pressure: 200 bar

fastening type: feet

Hydraulic cylinders UCJ6-L

Hydraulic cylinders UCJ6-L

Ponar

Product code: 732

Maximum characteristics:

piston diameter: 160 mm

piston rod diameter: 90 mm

working pressure: 200 bar

fastening type: feet

with position sensor

Plunger hydraulic cylinders UCN1, UCN2

Plunger hydraulic cylinders UCN1, UCN2

Ponar

Product code: 734

Maximum characteristics:

piston diameter: 80 mm

piston rod diameter: 30 mm

working pressure: 200 bar

rotary or spherical bearing

Hydraulic Cylinders: Their Types, Design and Application

A hydraulic cylinder is a mechanism whose work is to perform reciprocating movements under the pressure of a working fluid. This type of engine is used in all types of special equipment, including truck cranes, bulldozers, excavators, dump trucks, as well as industrial equipment (metallurgical and woodworking, presses, bending machines, lifts).

To buy a hydraulic cylinder exactly for your needs, you must first understand its types and device.

What are the types of hydraulic cylinders?

According to the principle of operation, the units are divided into single-acting, double-acting, telescopic and differential.

Single-acting cylinders are capable of working in one direction. They are set in motion by increasing the pressure of the working fluid in the cavity. A spring returns them to their initial position. This type is most often used in metal cutting machines, forging presses, lifting and transport, earthmoving and road construction equipment.

Double-acting cylinders are much more powerful than single-acting ones, because there is no need to overcome the spring return force when starting the cylinder. Such cylinders work in both directions and are widely used in all types of equipment.

Telescopic hydraulic cylinders are required to provide a greater stroke of the piston rod with small dimensions of the cylinder itself. This is necessary for the operation of cranes of various purposes. Telescopic hydraulic cylinders are also used in trucks to lift the body.

In differential units, two-way pressure is applied to the piston, taking into account the different pressure areas on each side. That is, the speed of movement is proportional to the ratio of the piston areas and inversely proportional to the total force. If the speed is higher, then the force is lower.

Hydraulic cylinders are also distinguished by actuators:

- Piston - available in two versions: with a single- or double-acting rod;

- Plunger - with a single-acting rod.

Hydraulic cylinders can be divided into two categories according to their application conditions:

- For driving lever mechanisms of working machines, providing cyclically repeating useful work (excavators with a single bucket, logging machines, front loaders);

- For positioning the entire machine or individual components in the required position or for outriggers to improve the stability of the machine.

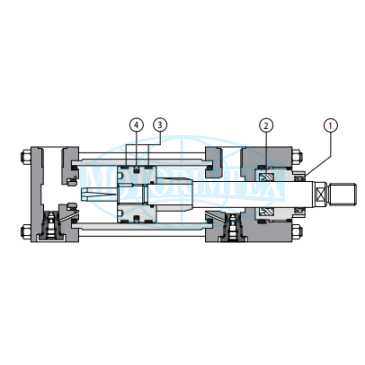

How is a hydraulic cylinder constructed?

In essence, the construction of this hydraulic engine is simple and consists of the following basic parts:

- Welded metal housing. This includes a sleeve to which the rear cover is screwed, and a front cover with a technological hole for the rod.

- Rod. This is the power element that takes on all the load when oil pressure is applied.

- Piston. It has a cylindrical shape and converts pressure energy into mechanical force by transmitting the force to the rod.

All connections, including moving ones, are reinforced and sealed with special seals. They are installed in the rods and pistons and protect the mechanism from sealing and loss of working pressure.

Where are hydraulic cylinders used?

Hydraulic cylinders are used in any machinery that uses a volumetric hydraulic drive, for example:

- Special equipment. Snowplows and sweeping machines, various tractor equipment.

- Machines for cutting materials. Exceptional precision can be achieved in mass production using hydraulic cylinders. They also provide additional safety for personnel and industrial equipment.

- Construction. This includes lifting and rotating devices.

- Thermoplastic molding machines. Thanks to hydraulic cylinders, quick drive and energy transmission can be achieved in production.

You can view the range of hydraulic cylinders in Ukraine and place an order on the Motorimpex company website. Our experts will calculate the price for any model of hydraulic cylinder for you. If you have difficulty choosing, contact our consultants by phone or email - they will help you order the necessary goods at the best price. Contact us!