Control-measuring devices purity grade sensors flow switch

Oil particle monitor of working fluid cleanliness class LDP100

Oil particle monitor of working fluid cleanliness class LDP100

IFM

Product code: 5136

sensitivity: 4, 6, 14, 21 µm

measurement error: ± 1%

maximum working pressure: 420 bar

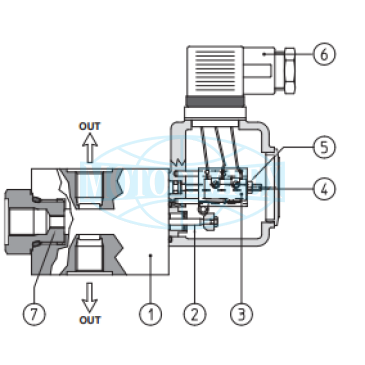

Flow switch FLS

Flow switch FLS

Atos

Product code: 1072

G1/4

measuring range: 0.2–4 l/min

maximum working pressure: 30 bar

In-line contamination monitor ICM - 2.0

In-line contamination monitor ICM - 2.0

MPFiltri

Product code: 5477

sensitivity: 4, 6, 14, 21, 25, 38, 50, 70 µm

monitoring time: 10–3600 s

measurement accuracy: ± 0,5% (4, 6, 14 µm), ± 1% (21, 25, 38, 50, 70 µm)

maximum working pressure: 420 bar

In-line contamination Monitor ICM

In-line contamination Monitor ICM

MPFiltri

Product code: 5138

sensitivity: 4, 6, 14, 21, 25, 38, 50, 70 µm

monitoring time: 10–3600 s

measurement error: ± 0,5% (4, 6, 14 µm), ± 1% (21, 25, 38, 50, 70 µm)

maximum working pressure: 400 bar

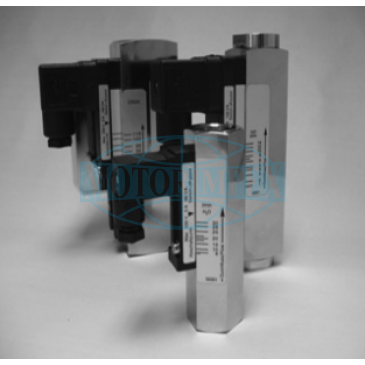

Electro-mechanical Flow Switch HFS 2100

Electro-mechanical Flow Switch HFS 2100

Hydac

Product code: 3206

G1/4–G1

measuring range: 0.5–110 l/min

maximum working pressure: 350 bar

Electro-mechanical Flow Switch HFS 2500

Electro-mechanical Flow Switch HFS 2500

Hydac

Product code: 3207

G1/4–G1 1/2

measuring range: 0.2–150 l/min

maximum working pressure: 350 bar

Contamination Sensor CS 1000

Contamination Sensor CS 1000

Hydac

Product code: 5141

sensitivity: 4, 6, 14, 21 µm

measurement accuracy: ± 0.5%

maximum working pressure: 350 bar

Contamination Sensor CS2000

Contamination Sensor CS2000

Hydac

Product code: 5140

sensitivity: 2, 4, 5, 6, 14, 15, 21, 25, 50 µm

measurement accuracy: ± 0.5%

maximum working pressure: 350 bar

Oil Condition Sensor HLB 1300

Oil Condition Sensor HLB 1300

Hydac

Product code: 5139

G3/4

maximum working pressure: 50 bar

measurement accuracy: ± 3%

Combined programmable flow sensors SA3010 (display)

Combined programmable flow sensors SA3010 (display)

IFM

Product code: 3830

internal thread: M26x1.5

sonde length: 19 mm

measuring range: 0–40 l/min

maximum working pressure: 30 bar

relay output

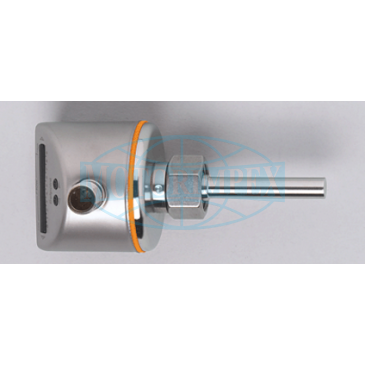

Programmable flow switch and SI0556 temperature (display)

Programmable flow switch and SI0556 temperature (display)

IFM

Product code: 3829

internal thread: M18x1.5

sonde length: 45 mm

measuring range: 3–300 cm/s

temperature measuring range: 2–80 °C

maximum working pressure: 300 bar

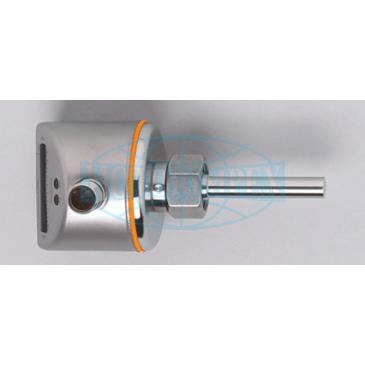

Programmable flow switch SI0557 (display)

Programmable flow switch SI0557 (display)

IFM

Product code: 3828

internal thread: M18x1.5

sonde length: 45 mm

measuring range: 3–300 cm/s

maximum working pressure: 30 bar

Programmable flow switch SI1106 (display)

Programmable flow switch SI1106 (display)

IFM

Product code: 3827

internal thread: M18x1.5

sonde length: 45 mm

measuring range: 3–300 cm/s

maximum working pressure: 300 bar

Programmable flow switch SI5002 (display)

Programmable flow switch SI5002 (display)

IFM

Product code: 3826

internal thread: M18x1.5

sonde length: 45 mm

measuring range: 3–300 cm/s

maximum working pressure: 300 bar

Programmable flow switch SI5003 (display)

Programmable flow switch SI5003 (display)

IFM

Product code: 3825

internal thread: M18x1.5

sonde length: 45 mm

measuring range: 3–300 cm/s

maximum working pressure: 300 bar

Programmable flow switch SI5006 (display)

Programmable flow switch SI5006 (display)

IFM

Product code: 3824

internal thread: M18x1.5

sonde length: 45 mm

measuring range: 3–300 cm/s

maximum working pressure: 300 bar

Programmable flow and temperature switch SI5007 (display)

Programmable flow and temperature switch SI5007 (display)

IFM

Product code: 3823

internal thread: M18x1.5

sonde length: 45 mm

measuring range: 3–300 cm/s

temperature measuring range: 2–80 °C

maximum working pressure: 300 bar

Control-measuring devices systems

Functional purpose of control-measuring device for hydraulic system

Control-measuring devices are special units which help you to get information about on the state of technological processes in the hydraulic system by measuring their parameters. These devices also serve for controlling different technical processes, increase productivity and guarantee safety work of hydraulic system.

Processing and measuring hydraulic parameters is a must in order to minimize the risk of equipment failures.

In the range of control-measuring devices for hydraulic systems our company offers:

- hydraulic pressure sensors;

- flow sensors;

- temperature sensors;

- oil level sensors;

- cleanliness class sensors;

- moisture content sensors;

- flow speed sensors;

- hydraulic pressure relay;

- temperature relay;

- oil level relay;

- viscometers;

- inductive sensors;

- limit switches;

- portable measuring instruments;

- digital displays.