- Hydraulic equipment catalog

- Manometers

Manometers

We are a leading supplier of hydraulic pressure gauges in Ukraine. Such a wide pressure range is represented only by us.

A significant portion of the models is always in stock. All nomenclature listed in the technical catalogs is available for order.

G1/4; G1/2

dial diameter: 70 mm

measuring range: -1–25 bar; 0–600 bar

G1/2

dial diameter: 67 mm

measuring range: -1/0 bar; 0–700 bar

G1/4, G1/2

maximum working pressure: 400 bar

М16х1,5, М16х2, G1/4, G1/2

G1/8, G1/4, G1/2

dial diameter: 40, 50, 63, 80, 100, 150 mm

measuring range: -1 +15 bar; 0–1600 bar

G1/8, G1/4, G1/2

dial diameter: 40, 50, 63, 80, 100, 150 mm

measuring range: -1 +15 bar; 0–1000 bar

G1/8, G1/4, G1/2

dial diameter: 40, 50, 63, 80, 100, 150 mm

measuring range: -1 +15 bar; 0–1000 bar

G1/8, G1/4, G1/2

dial diameter: 40, 50, 63, 80, 100, 150 mm

measuring range: -1 +15 bar; 0–1000 bar

G1/8, G1/4, G1/2

dial diameter: 40, 50, 63, 80, 100, 150 mm

measuring range: -1 +15 bar; 0–1000 bar

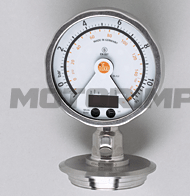

G1/4

dial diameter: 63 mm

measuring range: 0–400 bar

G1/4, G1/2

dial diameter: 63 or 100 mm

measuring range: -1–600 bar

measuring range: -1–600 bar

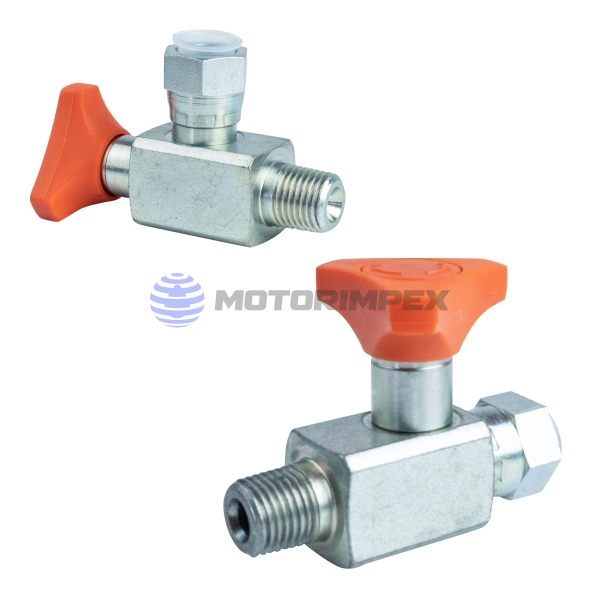

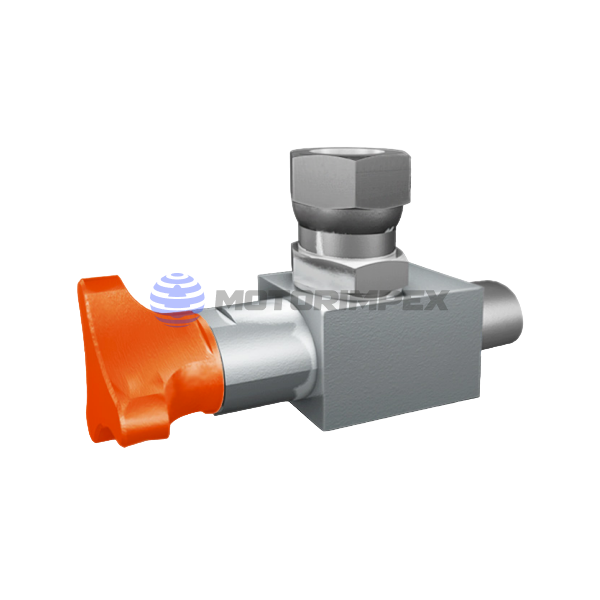

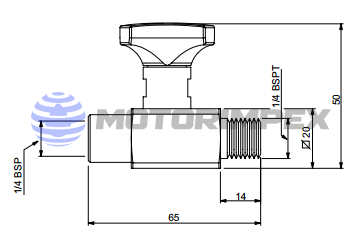

G1/4

maximum working pressure: 600 bar

G1/4, G3/8, G1/2

G1/4

maximum working pressure: 400 bar

dial diameter: 100 mm

measuring range: -1–10 bar

G1/2

dial diameter: 100 mm

measuring range: -1–1 bar

G1/2

dial diameter: 100 mm

measuring range: 0–400 bar

G1/2

dial diameter: 100 mm

measuring range : -1–25 bar

G1/2

dial diameter: 100 mm

measuring range: 0–100 bar

G1/2

dial diameter: 100 mm

measuring range: -1–25 bar

G1/2

dial diameter: 100 mm

measuring range: -1–10 bar

G1/2

dial diameter: 100 mm

measuring range: -1–4 bar

G1/2

dial diameter: 100 mm

measuring range: -0.125–2.5 bar

G1/2

dial diameter: 100 mm

measuring range: -0.05–1 bar

G1/2

dial diameter: 100 mm

measuring range: -12.5–250 mbar

G1/2

dial diameter: 100 mm

measuring range: -5–100 mbar

G1

dial diameter: 100 mm

measuring range: -1–10 bar

G1

dial diameter: 100 mm

measuring range: -5–100 mbar

G1

dial diameter: 100 mm

measuring range: -1–25 bar

G1

dial diameter: 100 mm

measuring range: -1–10 bar

G1

dial diameter: 100 mm

measuring range: -1–4 bar

G1

dial diameter: 100 mm

measuring range: -0.124–2.5 bar

G1

dial diameter: 100 mm

measuring range: -0.05–1 bar

G1

dial diameter: 100 mm

measuring range: -12.4–250 mbar

G1

dial diameter: 100 mm

measuring range: -1–1 mbar

G1

dial diameter: 100 mm

measuring range: -5–100 mbar

G1

dial diameter: 100 mm

measuring range: -1–25 bar

G1

dial diameter: 100 mm

measuring range: -1–10 bar

G1

dial diameter: 100 mm

measuring range: -0.124–2.5 bar

G1

dial diameter: 100 mm

measuring range: -0.124–2.5 bar

G1

dial diameter: 100 mm

measuring range: -0.05–1 bar

G1

dial diameter: 100 mm

measuring range: -12.4–250 mbar

G1

dial diameter: 100 mm

measuring range: -1–1 bar

G1/8, G1/4, G3/8

dial diameter: 63 mm

measuring range: 0–600 bar

Category description

Hydraulic manometers

A manometer is a high-precision device, a mechanical or electrical manometer. The hydraulic manometer measures the pressure in the working fluid system, which can be oils, gases and water. Such a device works on the principle of the reaction of a liquid to a force applied on one side.

Types of hydromanometers

In general, pressure meters are divided into two groups:

- Radial. In such a meter, the scale is perpendicular to the ground, and the fitting – connection point with the – is at the bottom.

- Axial or axial. In them, the scale is parallel to the ground, and the fitting is located on the back side.

However, the location of the fitting does not affect the accuracy of measuring the pressure of gases, water and other liquids, as well as the range of atmospheres. At the same time, the placement of the fitting does not affect the type of working fluid the device can work with.

By design, manometers for hydraulics are of the following types:

- Hydraulic or fluid. They work due to the position of the fluid in the ring or arc. Both sides can be the same or one of them acts as a small reservoir. In the arc model, the system exerts pressure on one end of the arc while the other end of the hydrometer rises. An increase in pressure leads to a greater displacement of the fluid in the curved tube. Therefore, such a hydromanometer is also called a pipe one.

- Pistons. The main elements are a stock with loads – they bring the system into balance. This is the most accurate instrument for calibrating, grading and verifying manometers. The error is from 0.05% to 0.1%. Wide operating range, high measurement repeatability and stability – undeniable advantages of such a unit.

- Deformative. The principle of operation is based on the use of deformation of an elastic sensitive element. It occurs under the influence of pressure, which is measured. The value of this strain is then transmitted to a reading device in a device with calibrated pressure units.

Which manometer to buy for measuring pressure in a hydraulic system?

To make the right choice when buying a manometer, you need to consider the following parameters:

- Scale value – pressure measuring range. To determine it, it is necessary that the working pressure in the system fluctuate in the scale interval from ⅓ to ⅔.

- Accuracy class – error indicator. The lower the value, the smaller the error.

- Size – manometer diameter.

- Type of connection (radial or axial).

- Degree of protection and case material. If the device will be used for domestic needs, there is no need for increased strength. For specific needs, the manufacturer's recommendations and operating conditions should be taken into account.

You can choose a manometer for measuring high pressure in our catalog. We offer reasonable prices, excellent quality and delivery to Kyiv and other cities of Ukraine.

Our experts will advise you on diagnosing pressure in hydraulic systems and help you choose the right manometer.

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

for ZF trucks

maximum continuous torque: 300 N∙m

G1/8, М5х0,8, G1/4, G3/8, G1/2

scheme: 5/2, 5/3

max. number of cycles per sec.: 5

response time: 0,05 sec