Hydraulic Power Units: Specifications, Features, Applications in Various Industries, and Key Aspects of Manufacturing

The actuating components of various devices and mechanisms cannot operate without energy transmission. This energy is supplied by specialized equipment known as a hydraulic power unit (HPU) or oil station. A hydraulic power unit is a hydraulic pump assembly that converts various forms of energy into mechanical energy of a working fluid, which is then supplied to the actuating parts of the system.

Types

Hydraulic stations can be classified based on several criteria. By mobility:

• Self-propelled;

• Stationary;

• Mobile.

By type of drive:

• Gasoline-powered;

• Manual;

• Electric.

By control method:

• Automatic;

• Manual;

• Remote-controlled.

These units are used as integral elements of mechanisms that facilitate mechanical operations. The primary function of a hydraulic power unit is to supply hydraulic fluid to the hydraulic system.

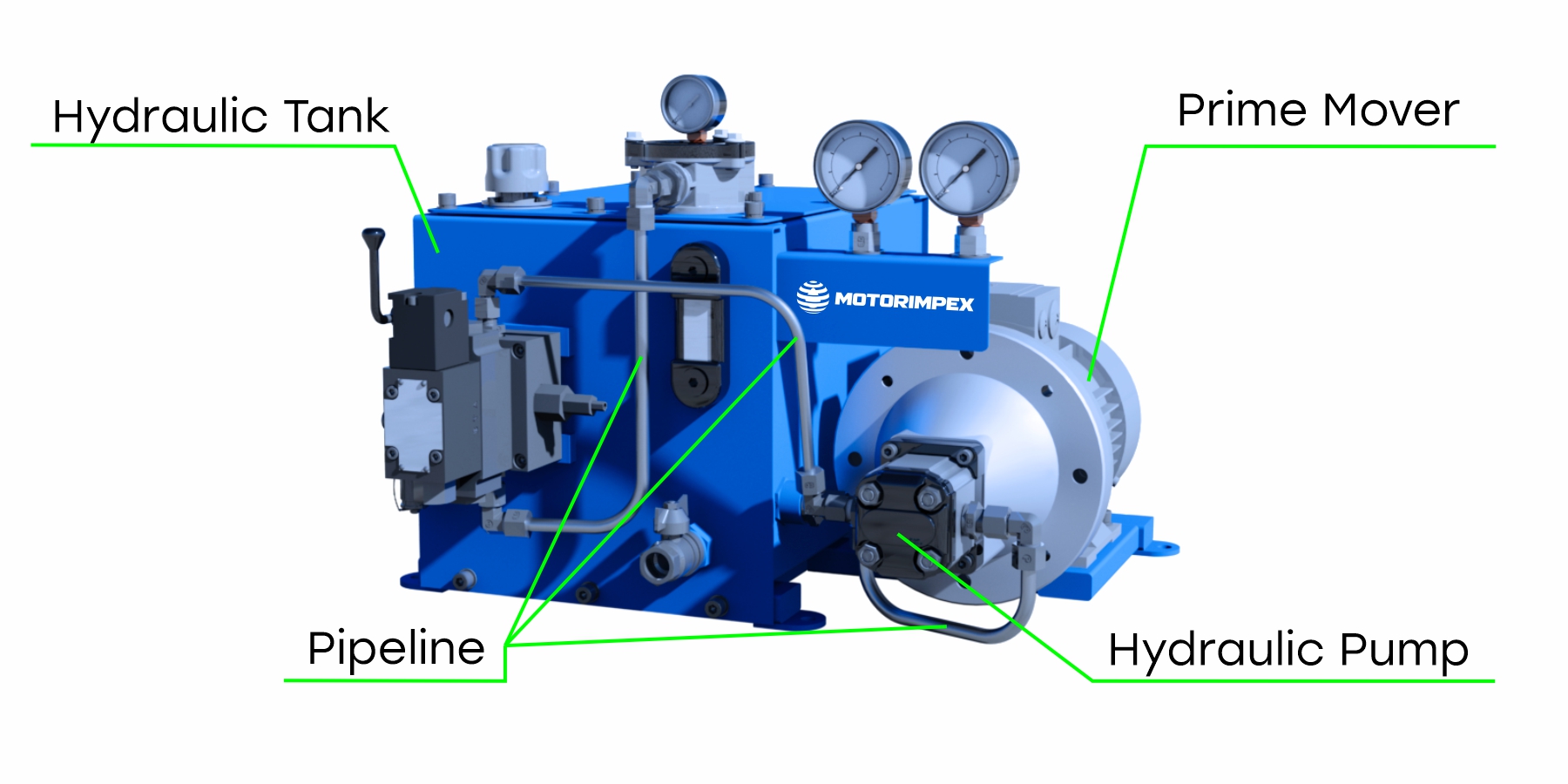

Structure of a Hydraulic Power Unit

Regardless of the type or size, a hydraulic power unit typically consists of the following components:

1. Tank. A plastic or metal vessel designed to store the working fluid. It includes a filler neck with a filter. The reservoir enables energy transfer to the hydraulic system.

2. Hydraulic Pump. Converts kinetic or mechanical energy into hydraulic energy. Pump types may vary, including gear, vane, or piston (plunger) designs.

3. Prime Mover (Drive Motor). Converts input energy (e.g., electric or combustion) into mechanical energy in the form of rotational or reciprocating motion.

4. Piping System. A network of lines connecting the pump, directional control valves, and other regulating or control components.

The hydraulic power unit is also equipped with filters to clean the returning fluid before it re-enters the tank.

Operating Principle

The hydraulic power unit operates as a closed-loop system. Initially, the prime mover starts the pump, which draws the fluid through the filter and into the piping system. The fluid is then directed through the control valve assembly to the actuators.

After performing its function, the fluid returns through filters to the reservoir, where the cycle repeats. Operating sequence:

1. Activation. The electric motor starts the hydraulic pump.

2. Fluid Intake. The pump draws the hydraulic fluid from the reservoir.

3. Filtration. The fluid passes through filter elements to remove contaminants.

4. Distribution. Clean fluid is delivered to the control valve, which directs flow to the required actuators

5. Return Cycle. Once the working cycle is completed, the fluid returns to the reservoir for potential secondary filtration (depending on the unit design).

The configuration and additional components may vary depending on the model and operating conditions. Unit performance is monitored using pressure, temperature, and level indicators.

Purpose and Application

Hydraulic power units are used across multiple industries wherever equipment requires stable hydraulic pressure and flow.

In metallurgy: hydraulic power units supply rolling mills, metal shears, and forming lines..

In mechanical engineering and heavy equipment: they power presses, lifts, crushers, and test benches.

In energy production: they control turbines, gates, and shut-off valves.

In agriculture: they operate balers, combines, sprayers, and grain processing systems..

In construction and woodworking: they power sawmills, concrete forming equipment, and machine tools.

Due to their modular and customizable design, hydraulic power units are suitable for both large industrial systems and compact mobile machinery.

Where to Find Hydraulic Power Units

The Motorimpex Manufacturing Company designs and produces hydraulic power units tailored to specific customer requirements — from compact assemblies to high-capacity systems with motors over 250 kW and large-volume tanks. We account for working pressure, flow rate, and operating conditions, integrating cooling or heating systems for stable operation under extreme environments.

Our solutions are successfully implemented at facilities across Ukraine and Europe, ensuring reliable operation of presses, machine tools, mining, and municipal equipment. With flexible manufacturing and an extensive component inventory, we offer short lead times and direct technical support.

|

Model |

Price |

Lead Time |

|

Hydraulic power unit of 2233 series for roll forming equipment |

from ₴95,000 |

4-6 weeks |

|

Hydraulic power unit of 1551 series for stationary manipulators |

from ₴145,000 |

4-8 weeks |

|

Hydraulic power unit of 1727 series for vertical milling machines |

from ₴195,000 |

4-8 weeks |

|

Hydraulic power unit of 2297 series for vertical milling machines |

from ₴245,000 |

8-12 weeks |

|

Hydraulic power unit of 3110 series for the jack in both the "Lift" and "Lower" modes |

from ₴295,000 |

8-12 weeks |

By choosing Motorimpex, you receive a comprehensive, turnkey hydraulic solution. Submit your request or send us your technical specification – and we will design the optimal configuration that meets your requirements and reduces project commissioning time.