- Hydraulic equipment catalog

- Heat exchangers

Heat exchangers

We are the largest supplier of hydraulic oil heat exchangers in Ukraine. Most of the product manufacturers are represented exclusively.

A wide selection of models is always in stock. All nomenclature listed in the technical catalogs is available for order.

maximum flow rate: 110 l/min

maximum operating temperature: 120°C

DC 12/24 V

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

maximum cooling capacity: 0.35 kW/ºC

maximum flow rate: 90 l/min

tank capacity: 18 l

DC 24 V

maximum cooling capacity: 1.3 kW/ºC

maximum flow rate: 320 l/min

AC 230/400 V, 50/60 Hz

DC 12/24 V

compatible fluids: hydraulic oils, water-oil emulsions

maximum cooling capacity: 200 kW

maximum flow rate: 550 l/min

compatible fluids: hydraulic oils

maximum cooling capacity: 0.9 kW/ºC

maximum flow rate: 260 l/min

DC 12/24 V

compatible fluids: hydraulic oils, water-oil emulsions

maximum cooling capacity: 0.4 kW/ºC

maximum flow rate:60 l/min

tank capacity: 15 or 18 l

DC 12/24 V

compatible fluids: hydraulic oils, water-oil emulsions

maximum cooling capacity: 0.71 kW/ºC

maximum flow rate: 50 l/min

AC 230/460 V, 50/60 Hz

DC 12/24 V

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

maximum cooling capacity: 7.5 kW/ºC

maximum flow rate: 900 l/min

AC 230/480 V, 50/60 Hz

DC 12/24 V

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

maximum cooling capacity: 3.2 kW/ºC

maximum flow rate: 560 l/min

AC 230/400 V, 50/60 Hz

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

maximum cooling capacity: 7 kW/ºC

maximum flow rate: 625 l/min

AC 230/795 V, 50/60 Hz

compatible fluids: hydraulic oils, water-in-oil emulsions, aqueous glycol solutions

apply for mobile equipment

maximum cooling capacity: 0.5 kW/ºC

maximum flow rate:100 l/min

maximum tank capacity: 30 l

DC 12/24 V

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

maximum cooling capacity: 320 kW

maximum flow rate: 800 l/min

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions , water/industrial water

maximum cooling capacity: 2.9 kW/ºC

maximum flow rate: 500 l/min

AC 230/400 V, 50/60 Hz

DC 12/24 V

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

maximum cooling capacity: 1.3 kW/ºC

maximum flow rate: 320 l/min

AC 230/460 V, 50/60 Hz

DC 12/24 V

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

maximum cooling capacity: 1 kW/ºC

maximum flow rate: 400 l/min

AC 230/400 V, 50/60 Hz

DC 12/24 V

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

maximum cooling capacity: 0.55 kW/ºC

maximum flow rate: 350 l/min

DC 12/24 V

can be mounted on pump bracket

used as additional cooling elements

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

maximum cooling capacity: 110 kW

maximum flow rate: 110 l/min

AC 230/400V, 50/60 Hz

compatible fluids: hydraulic oils, water-oil emulsions, aqueous glycol solutions

maximum cooling capacity: 6.2 kW/ºC

maximum flow rate: 400 l/min

compatible fluids: hydraulic oils, water-in-oil emulsions, aqueous glycol solutions , water/industrial water

maximum flow rate: 28 l/min

AC 400/460 V, 50/60 Hz

compatible fluids: hydraulic oils

maximum flow rate: 80 l/min

AC 230/460 V, 50/60 Hz

compatible fluids: hydraulic oils

maximum cooling capacity: 1.25 kW/ºC

maximum flow rate: 300 l/min

AC 230/460 V, 50/60 Hz

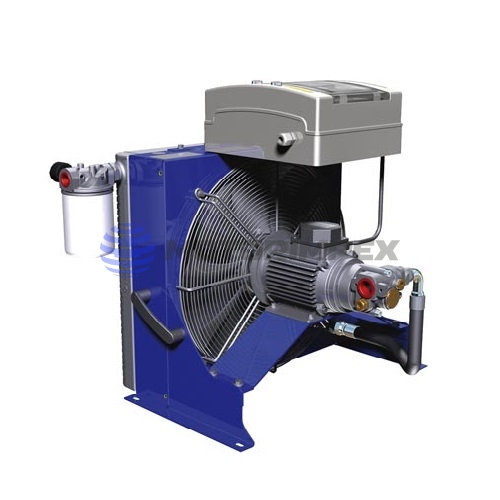

available with filter and pump

compatible fluids: hydraulic oils, aqueous glycol solutions

maximum cooling capacity: 6.7 kW/ºC

maximum flow rate: 840 l/min

AC 230/480 V, 50/60 Hz

Available with filter and pump

compatible fluids: hydraulic oils, aqueous glycol solutions

motor working volume: 6.3, 14 and 22 cm2/rev

maximum cooling capacity: 7.5 kW/ºC

maximum flow rate: 840 l/min

compatible fluids: hydraulic oils, aqueous glycol solutions

apply for mobile equipment

working volume of the hydraulic motor: 32 cm2/rev

DC 12/24 V

compatible fluids: hydraulic oils, aqueous solutions of glycol, diesel

maximum cooling capacity: 2.75 kW/ºC

maximum flow rate: 330 l/min

AC 220/480 V, 50/60 Hz

available with filter and pump

compatible fluids: hydraulic oils, aqueous glycol solutions

maximum cooling capacity: 230 kW

maximum flow rate: 330 l/min

AC 400 V, 40/70 Hz

compatible fluids: hydraulic oils, aqueous glycol solutions

motor working volume: 6.3, 14 and 22 cm2/rev

maximum cooling capacity: 1.4 kW/ºC

maximum flow rate: 250 l/min

AC 230/400 V, 50/60 Hz

compatible fluids: hydraulic oils, aqueous glycol solutions

maximum cooling capacity: 0.7 kW/ºC

maximum flow rate: 250 l/min

AC 230/400 V, 50/60 Hz

compatible fluids: hydraulic oils, aqueous glycol solutions

apply for mobile equipment

maximum cooling capacity: 0.9 kW/ºC

maximum flow rate: 180 l/min

DC 12/24 V

compatible fluids: hydraulic oils, aqueous glycol solutions

apply for mobile equipment

maximum cooling capacity: 13 kW

tank capacity: 15 l

DC 12/24 V

compatible fluids: hydraulic oils, aqueous glycol solutions, diesel

apply for mobile equipment

maximum cooling capacity: 15 kW

tank capacity: 15 l

compatible fluids: hydraulic oils, aqueous glycol solutions, diesel

maximum cooling capacity: 30 kW

compatible fluids: hydraulic oils, lubricating fluids, water, sea water, aqueous glycol solutions , refrigerants

valves, thermostats, temperature switches

maximum cooling capacity: 1.22 kW/ºC

maximum flow rate: 15 l/min

tank capacity: 5.5–70 l

AC 380/440 V, 50/60 Hz

compatible fluids: hydraulic oils, aqueous glycol solutions, antifreeze based on glycol, drinking water containing ethylene glycol or propylene

maximum cooling capacity: 100 kW

maximum flow rate:100 l/min

tank capacity: 7, 9.5, 21 and 70 l

compatible fluids: hydraulic oils, aqueous glycol solutions, antifreeze based on glycol, drinking water containing ethylene glycol or propylene

maximum cooling capacity: 15 kW

maximum flow rate:40 l/min

AC 230/460 V, 50/60 Hz

compatible fluids: hydraulic oils

maximum cooling capacity: 10 kW

maximum flow rate: 15 l/min

AC 380/480 V, 50/60 Hz

compatible fluids: hydraulic oils

maximum cooling capacity: 30 kW

maximum flow rate:60 l/min

compatible fluids: hydraulic oils

maximum cooling capacity: 90 kW

maximum flow rate: 185 l/min

compatible fluids: hydraulic oils

maximum cooling capacity: 6.7 kW

AC 230/460 V, 50/60 Hz

maximum cooling capacity: 155 kW

maximum flow rate: 250 l/min

AC 230/440 V, 50/60 Hz

compatible fluids: hydraulic oils, aqueous glycol solutions, water

maximum cooling capacity: 2.3 kW

maximum flow rate: 10 l/min

AC 230V, 50/60 Hz

maximum cooling capacity: 3 kW

AC 100/240V, 50/60 Hz

maximum cooling capacity: 22 kW

maximum flow rate: 66 l/min

AC 230/400 V, 50/60 Hz

maximum cooling capacity: 4.6 kW

maximum flow rate: 30 l/min

AC 230V, 50/60 Hz

maximum cooling capacity: 0.45 kW/ºC

maximum flow rate: 200 l/min

DC 12/24 V

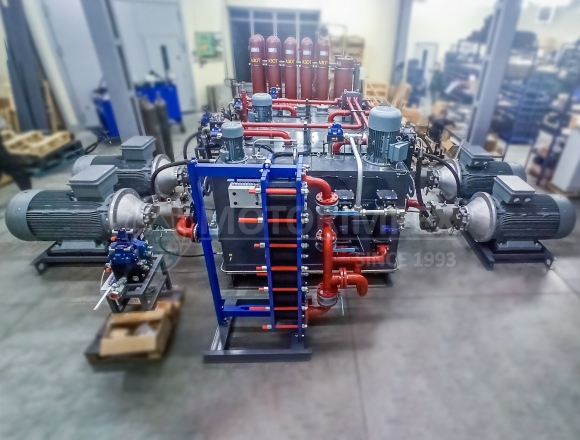

Category description

Air-oil coolers and heat exchangers: types and operating principles

A hydraulic oil cooler is a device based on the principle of heat transfer from one fluid circulating within it to another fluid moving in the hydraulic system.

Operating Principle of a Heat Exchanger

In a hydraulic system, oil is subjected to heating in gear transmissions through the friction of moving elements of mechanisms. Cooling occurs in one of two ways: with water or air.

As a result, the following types of heat exchangers are identified::

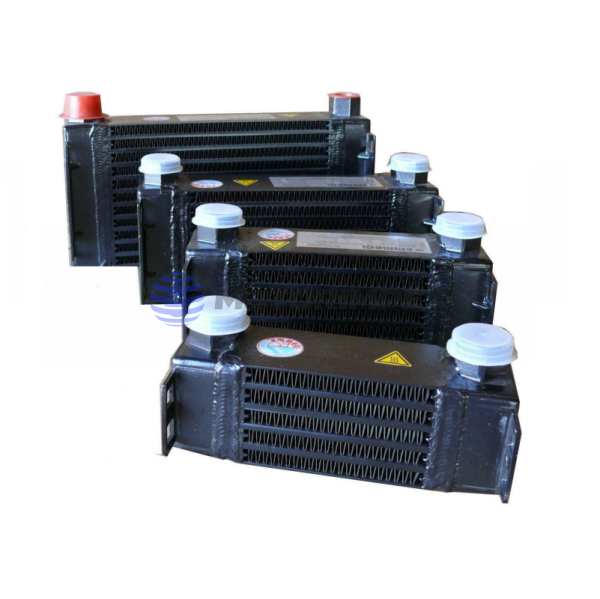

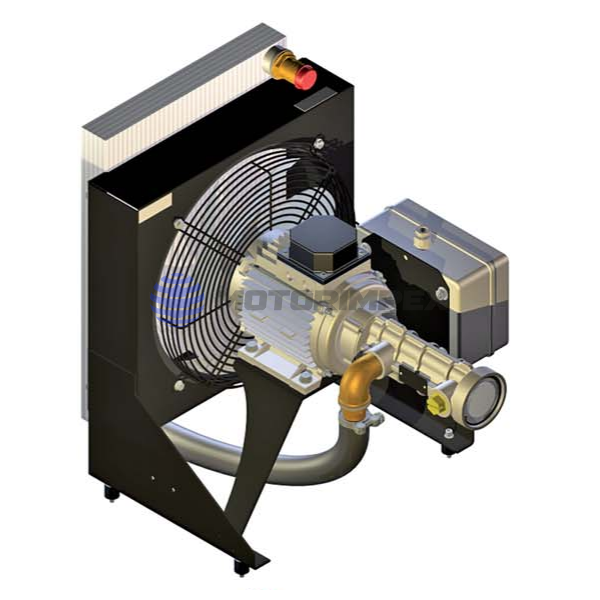

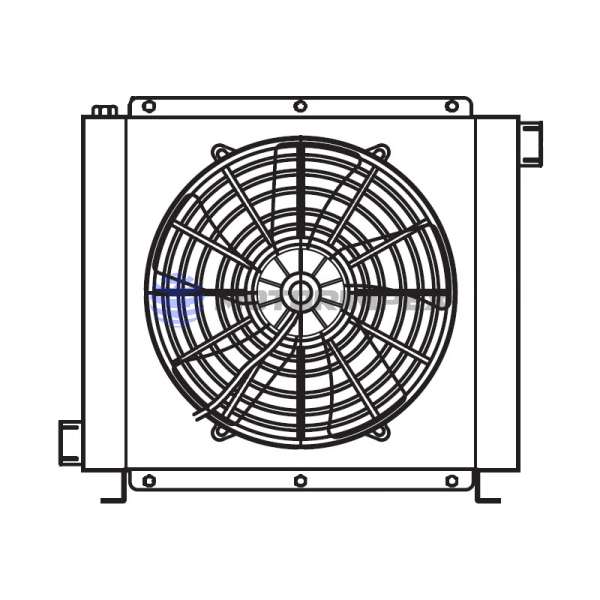

- Air Heat Exchangers for Oil Cooling – used in stationary and mobile equipment. The operating principle of such devices is that the oil requiring cooling is pumped through a system of pipes, which are cooled by an airflow generated by a fan.

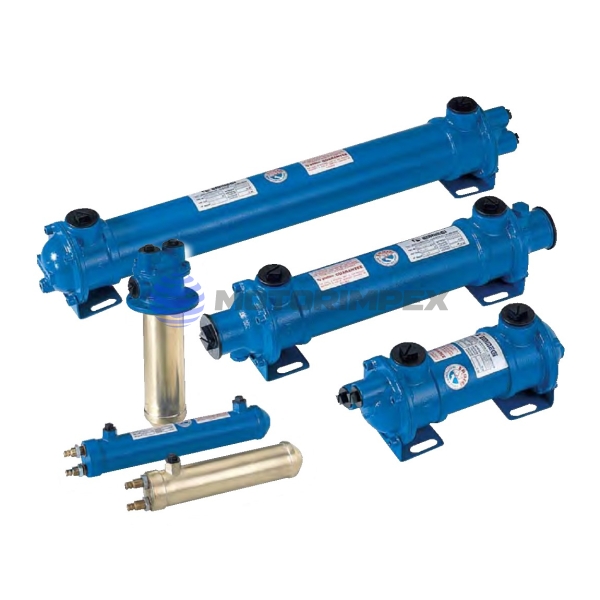

- Water Oil Coolers – used when it is necessary to cool the working fluid as effectively as possible.

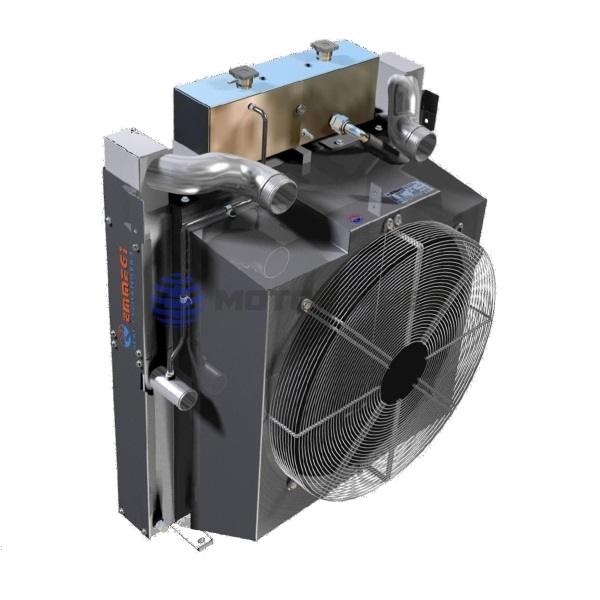

- Autonomous Cooling Systems – used in the absence of a circulating cooling system.

- Chillers – devices for cooling fluid that use an absorption or vapor compression refrigeration cycle. After cooling in the chiller, the fluid is supplied to heat exchangers to reduce air temperature and remove heat from the equipment.

Heat Exchangers are Classified into Two Types Based on Purpose:

- Air-Oil Coolers. The oil entering them is cooled to a certain temperature level. Due to the temperature difference between the surrounding environment (air, water) and the oil, heat is transferred through the walls of the pipes from the fluid to the environment, leading to its cooling.

- Oil Heaters. Used in conditions where oil systems are employed and it is necessary to heat the working fluid above its initial temperature.

In Which Fields are Heat Exchangers Used?

In the agricultural sector, oil coolers are actively used in most equipment with hydraulic components. Heat exchangers are also employed in metal cutting, sheet bending, and other metalworking machines. Foundry installations, including high-temperature casting machines under high pressure, use such equipment.

Generally, any heavy machinery (road, construction, etc.) is equipped with a hydraulic heat exchanger. Since various excavators, cranes, and loaders almost always operate with overheated oil, they require its cooling.

Welcome to the website of Motorimpex! Here you can choose from air and water oil coolers, chillers and autonomous cooling systems. We provide complete information for technical specifications and detailed diagrams.

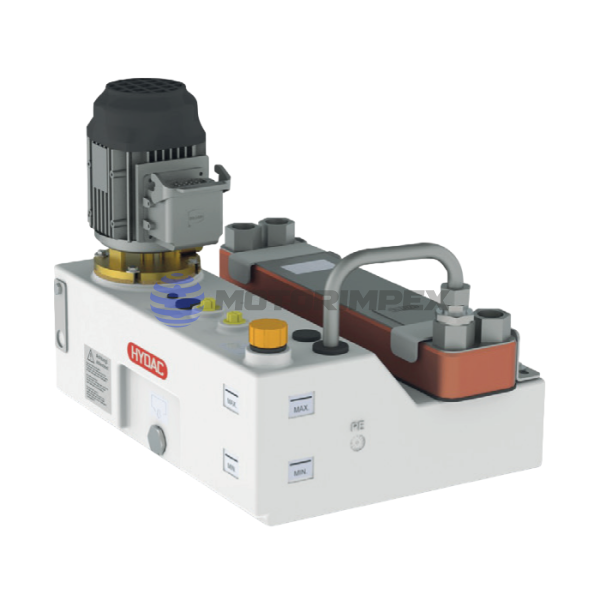

In our assortment you will find heat exchangers from such manufacturers as Hydac, Emmegi, OMT at affordable prices.

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

for ZF trucks

maximum continuous torque: 300 N∙m

G1/8, М5х0,8, G1/4, G3/8, G1/2

scheme: 5/2, 5/3

max. number of cycles per sec.: 5

response time: 0,05 sec