- Production of hydraulics

- Test benches

Test benches

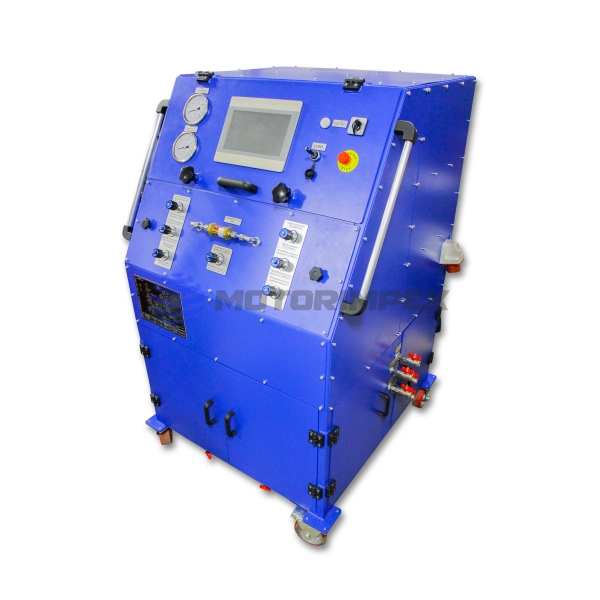

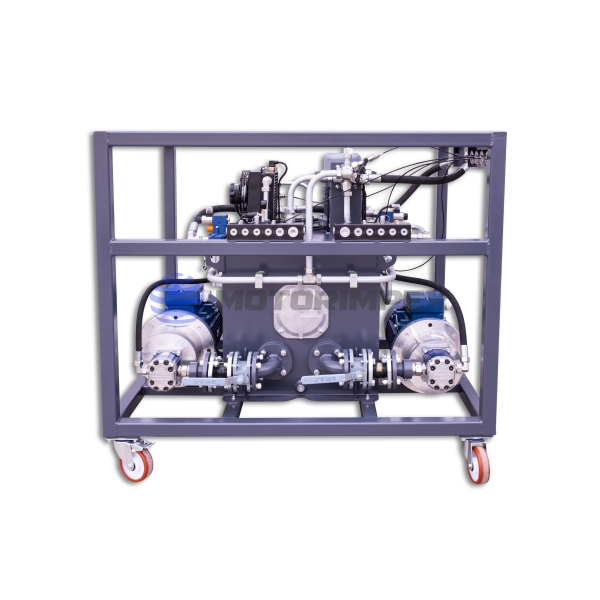

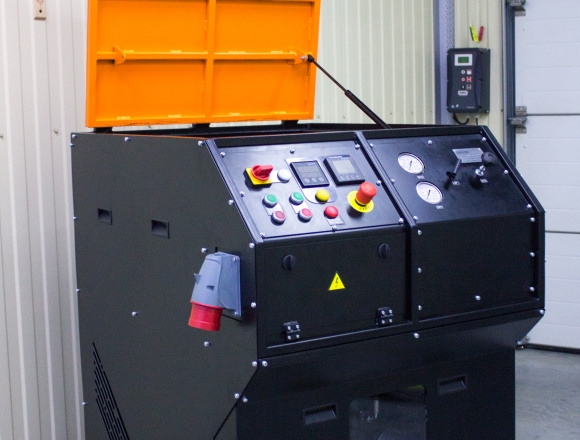

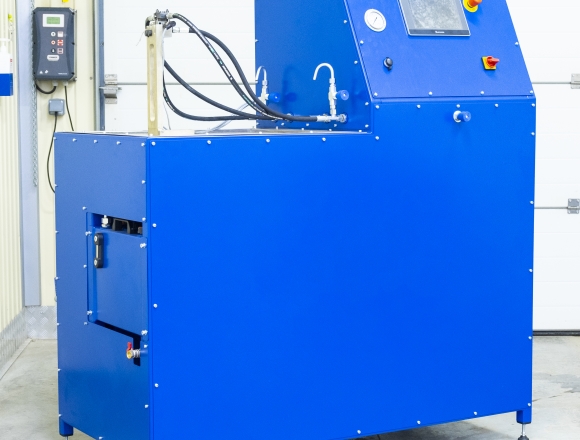

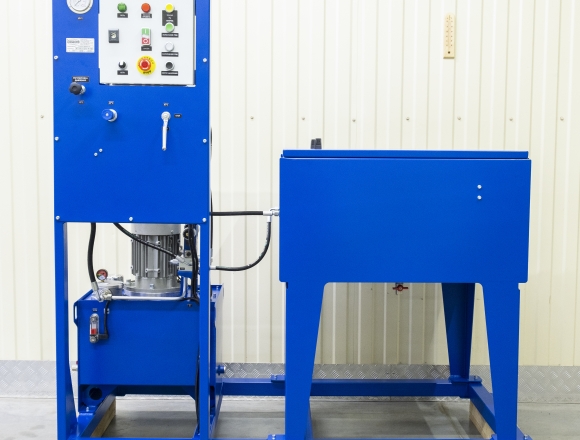

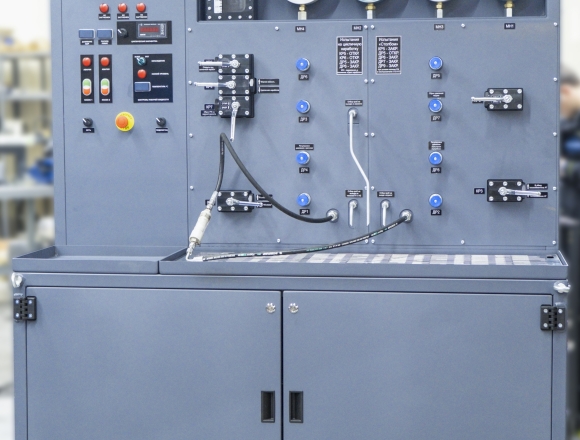

"Motorimpex" Production Enterprise designs and manufactures test benches. Our benches ensure accurate testing under high loads.

They are used to check the quality and performance in various industries. Our specialists guarantee high measurement accuracy and quality control at the respective production stage.

Category description

Hydraulic testing bench: purpose and features of choice

A hydraulic pump testing bench is a construction consisting of a power module, a testing module, and a working area for the operator. Electrical and hydraulic lines ensure the smooth operation of all bench elements.

What are Hydraulic Testing Benches Used for?

The main purpose of such devices is:

- Diagnosing and further improving the hydraulic devices and parts for them.

- Calculating various technical characteristics.

- Testing working capabilities under different loads.

- Determining the operating parameters of both new hydraulic units and repaired ones used in special equipment of various purposes: communal machines, quarrying and road-building equipment.

Many testing benches are equipped with new technologies that can easily detect breakdowns of varying complexity. They also help to increase or decrease the stiffness of the hydraulic system, based on the data obtained during testing.

Testing benches are used for testing the durability of vessels, tanks, and pipes by exposing them to temperature or mechanical stress. This ultimately reduces the amount of defective equipment or parts released, thus reducing the manufacturer's financial costs.

A hydraulic testing bench can demonstrate:

- Internal and external sealing;

- Pressure indicators that comply with standards;

- The functionality of hydraulic equipment;

- Problems that arose during the assembly of hydraulic mechanisms;

- Internal leakage of working fluid;

- Technical characteristics with subsequent preservation on an information carrier.

Advantages of Hydraulic Testing Benches

Modern hydraulic testing benches are equipped with electronic and hydraulic control systems, as well as various monitoring and measuring instruments and sensors.

Among the advantages of a hydraulic testing bench:

- Easy transportation, installation, and storage due to the dismantling structure;

- Process control using computer technologies;

- Reduced time and costs for testing hydraulic equipment;

- Opportunity to create and test equipment prototypes in advance;

- Reduced production costs due to the detection of defects and malfunctions at the stage of development and testing of equipment.

How to choose and buy a hydraulic test bench?

When choosing such a stand, it is necessary to take into account a number of factors.

- Cost. As a rule, inexpensive options are limited in functionality and capabilities, and therefore, they are less effective. High cost in this matter justifies itself, since a device with a wide range of functions has a significant payback period.

- Specifications. The stand should work with products and parts that have high demand, and also have suitable functionality to increase the number of potential customers.

- Completeness. It is important that the unit is equipped with all the devices and tools necessary for work. We are talking about a built-in hydraulic station, hydraulic or electric drive. It is also desirable for the stand to be able to transfer information to paper or digital media.

We invite you to familiarize yourself with the range of products on the website of the company Motorimpex. In our portfolio, there are stands made to individual characteristics for testing high-pressure hoses, grabbers, hydraulic motors, and other equipment from various fields.

We have many years of experience in designing and manufacturing stands in the Ukrainian market and are ready to implement the best solution for you. Hurry up and order now!

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

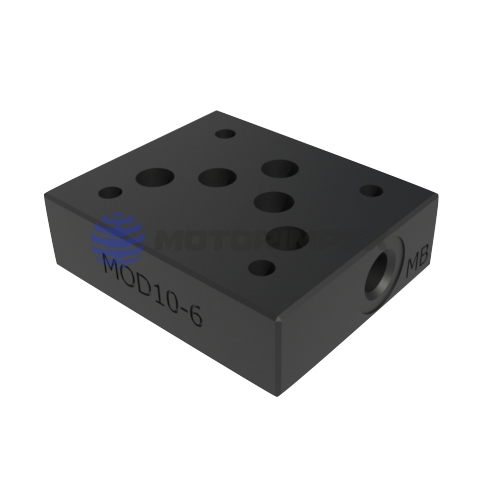

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

for ZF trucks

maximum continuous torque: 300 N∙m

G1/8, М5х0,8, G1/4, G3/8, G1/2

scheme: 5/2, 5/3

max. number of cycles per sec.: 5

response time: 0,05 sec