- Production of hydraulics

- Hydraulic manifolds

Hydraulic manifolds

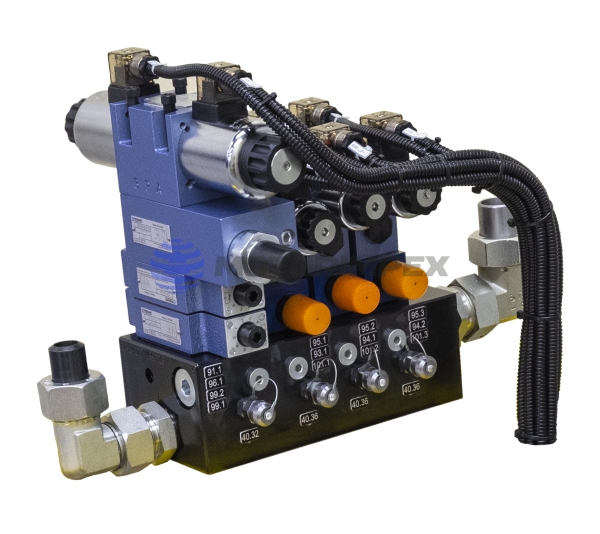

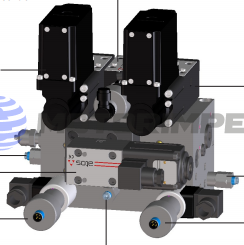

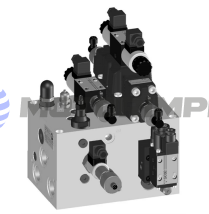

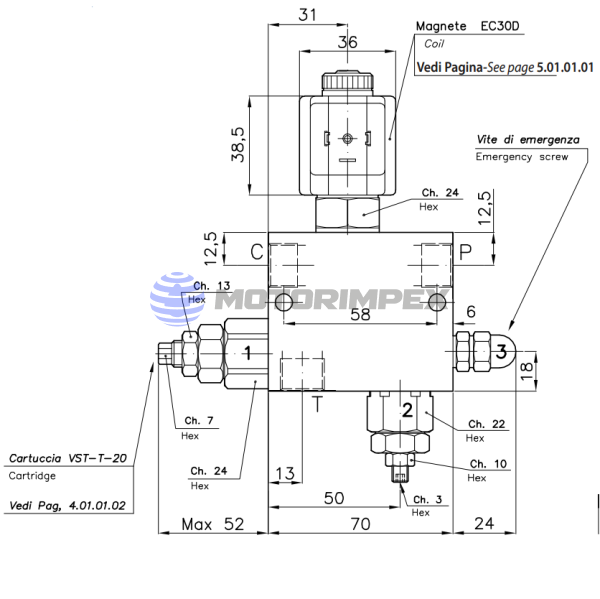

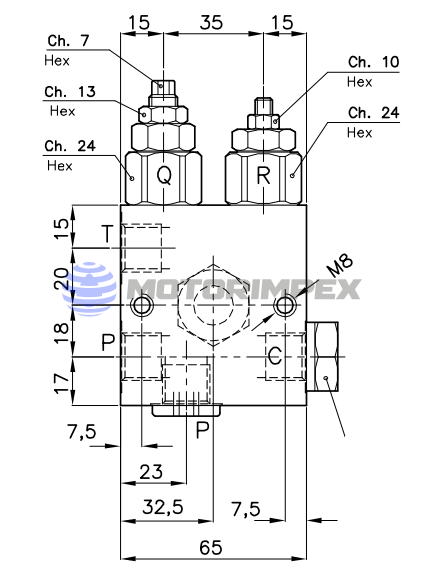

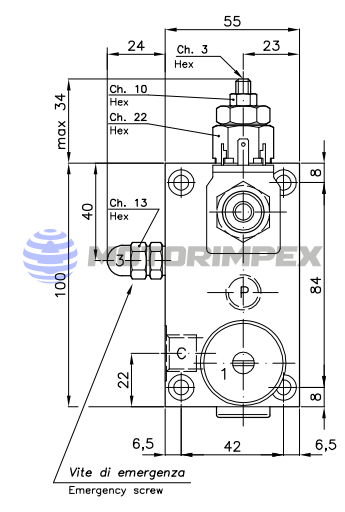

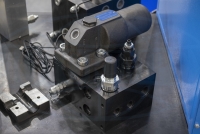

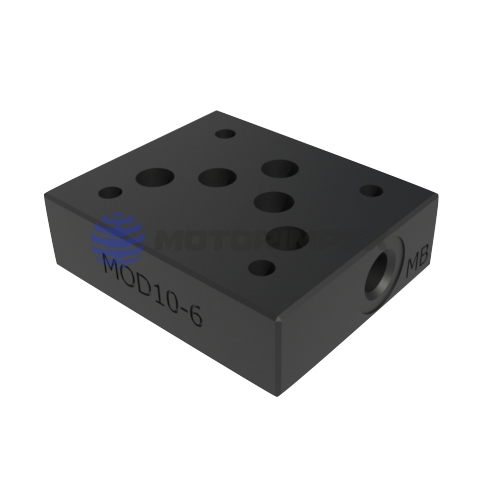

"Motorimpex" Production Enterprise designs and manufactures hydraulic manifolds, adapting them to specific customer requirements. The main purpose of using manifolds in hydraulic systems is to provide more efficient control of working fluid flows and at the same time simplify the design of hydraulic channels.

The manifold's base – the mounting plate – is milled on high-precision "Haas" machines. The components included in the hydraulic manifold are supplied by us from leading global hydraulic brands.

maximum working pressure: 350 bar

maximum flow rate: 160 l/min

maximum working pressure: 350 bar

maximum flow rate: 250 l/min

maximum working pressure: 350 bar

maximum flow rate: 100 l/min

maximum working pressure: 350 bar

maximum flow rate: 160 l/min

maximum working pressure: 500 bar

maximum flow rate: 100 l/min

Our partners offers

G1/2

maximum flow rate: 35 l/min

SAE version

SAE 3/4", SAE 1", SAE 1 1/4"

maximum working pressure: 350 bar

maximum flow rate: 400 l/min

G1/4, G3/8, G1/2

maximum working pressure: 350 bar

maximum flow rate: 40 l/min

with hydraulic synchronization

maximum working pressure: 315 bar

maximum flow rate: 160 l/min

with manual synchronization

maximum working pressure: 315 bar

G1/4, G3/8

maximum working pressure: 350 bar

maximum flow rate: 150 l/min

G1/2

maximum working pressure: 350 bar

maximum flow rate: 60 l/min

G1/2

maximum working pressure: 350 bar

maximum flow rate: 60 l/min

G3/4

maximum working pressure: 350 bar

maximum flow rate: 80 l/min

G3/8

maximum working pressure: 350 bar

maximum flow rate: 40 l/min

G1/4, G3/8

maximum working pressure: 350 bar

maximum flow rate: 40 l/min

G3/8

maximum working pressure: 350 bar

maximum flow rate: 40 l/min

G3/8

maximum working pressure: 350 bar

maximum flow rate: 40 l/min

G3/8

maximum working pressure: 350 bar

maximum flow rate: 40 l/min

Category description

Hydraulic manifolds and their applications

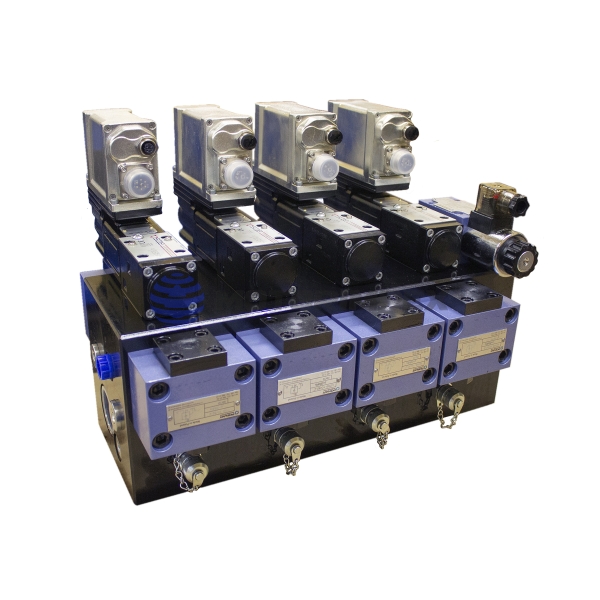

A hydraulic manifold is a complex of hydraulic elements used to supply oil to a hydraulic system at specified flow rates. The hydraulic components are interconnected by channels inside the manifold block.

In general, a manifold includes a block with hydraulic distributors, valves, and locks mounted on or in it. They control the hydraulic energy required by hydraulic cylinders or hydraulic motors of any kind. The unique feature of a hydraulic manifold is that it can be located independently of the source of hydraulic energy and the actuator of the equipment for which the manifold is intended.

When purchasing a hydraulic manifold, it is essential to determine clearly for what purposes and equipment it will be used.

Where Are Hydraulic Manifolds Used?

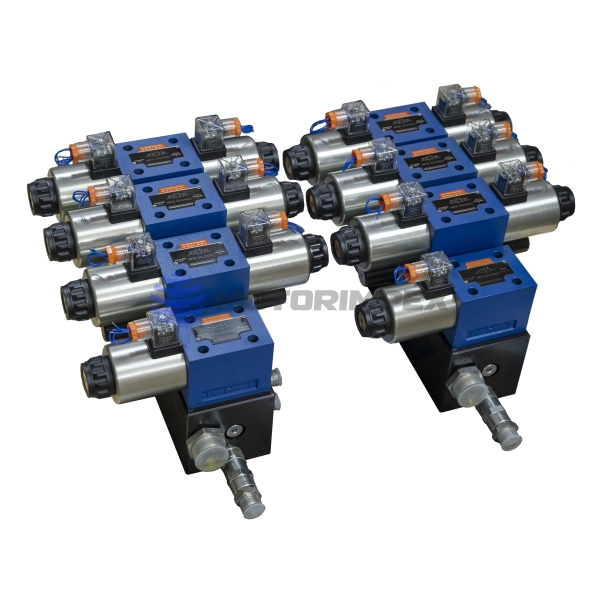

This component can be used in various fields where systematic lifting of heavy loads or repeated use of directed powerful force is required, as well as with various devices with drives.

Manifolds are used in:

- Waste compactors;

- Lifting equipment;

- Port graders;

- Security gates;

- Lifting platforms with a pantograph;

- Excavators;

- Lifts and hoists;

- Log loaders;

- Lifting work platforms.

Would you like to buy a hydraulic manifold in Ukraine in just a few clicks? Send a request to our engineers for calculating the production time and cost.

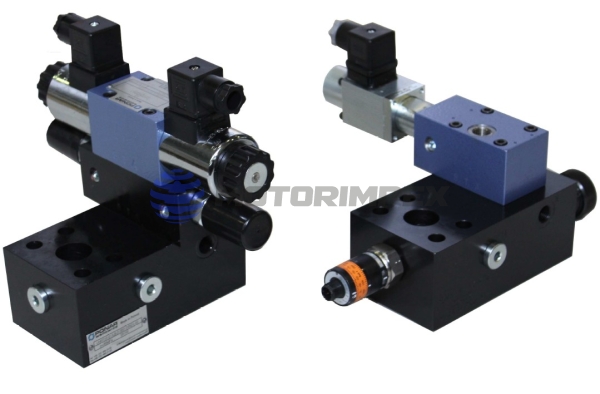

Motorimpex specializes in the design and manufacture of different types of hydraulic manifolds tailored to fully meet individual needs. We take into account the necessary dimensions, output pressures, ease of installation, and operation.

With us, you will get the required manifold at a reasonable price. Hurry up and place your order!

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

for ZF trucks

maximum continuous torque: 300 N∙m

G1/8, М5х0,8, G1/4, G3/8, G1/2

scheme: 5/2, 5/3

max. number of cycles per sec.: 5

response time: 0,05 sec