- Hydraulic equipment catalog

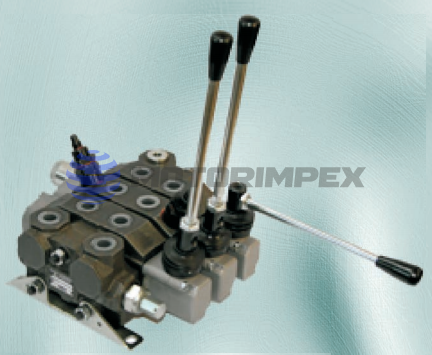

- Directional control valves

Directional control valves

We are a leader in the supply of hydraulic distributors in Ukraine. We have the largest hydraulic warehouses in the country, and a large part of the product brands is represented exclusively by us.

A wide range of product models is always in stock to quickly meet customer needs. All products listed in the technical catalogs are available for order.

DN 6

maximum working pressure: 320 bar

maximum flow rate: 80 l/min

DN 10

maximum working pressure: 320 bar

maximum flow rate: 140 l/min

up to 7 spool valves

maximum working pressure: 300 bar

maximum flow rate: 150 l/min

up to 10 sections

G1/2, G3/8

maximum working pressure: 320 bar

maximum flow rate: 80 l/min

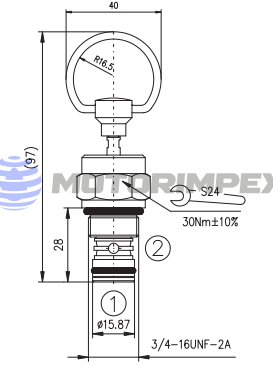

3/4–16 UNF

2-way

maximum working pressure: 250 bar

maximum flow rate: 45 l/min

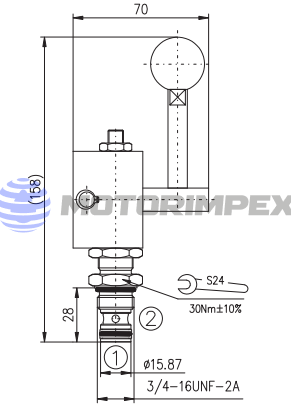

3/4–16 UNF

2-way

maximum working pressure: 250 bar

maximum flow rate: 9.5 l/min

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

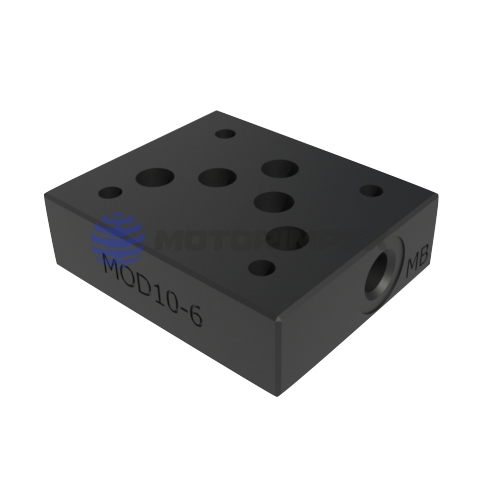

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

for ZF trucks

maximum continuous torque: 300 N∙m

G1/8, М5х0,8, G1/4, G3/8, G1/2

scheme: 5/2, 5/3

max. number of cycles per sec.: 5

response time: 0,05 sec