- Hydraulic equipment catalog

- Directional control valves

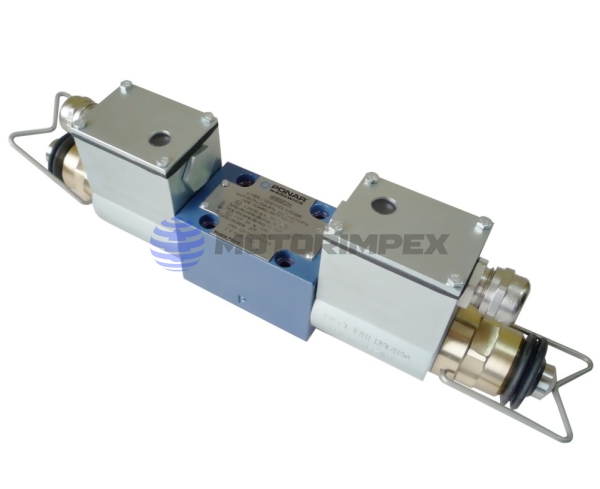

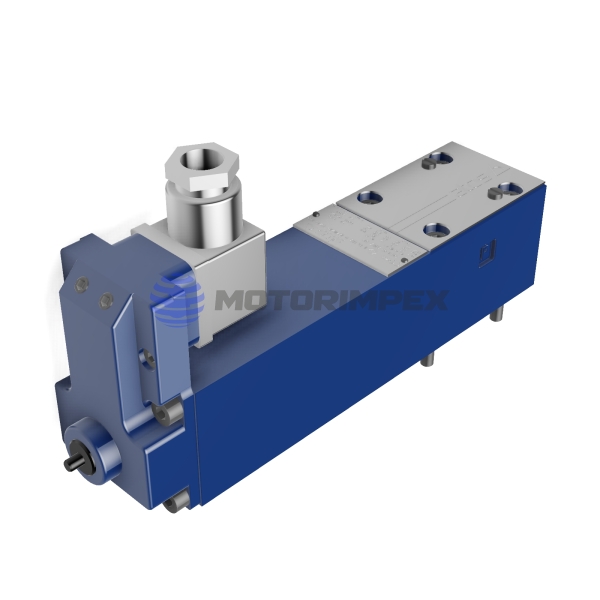

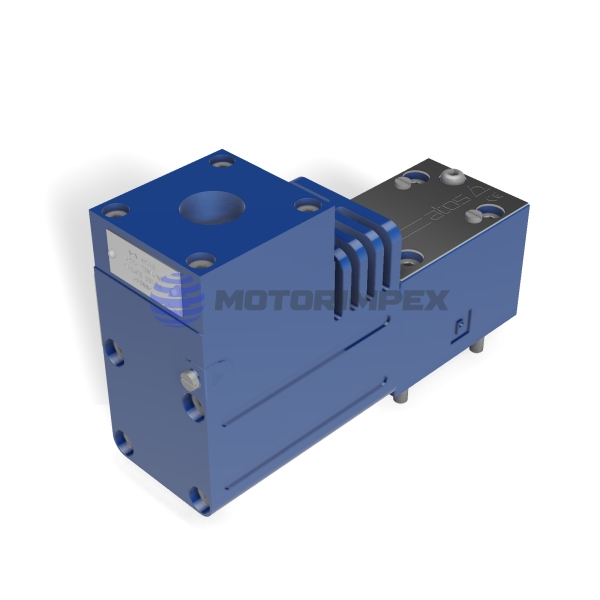

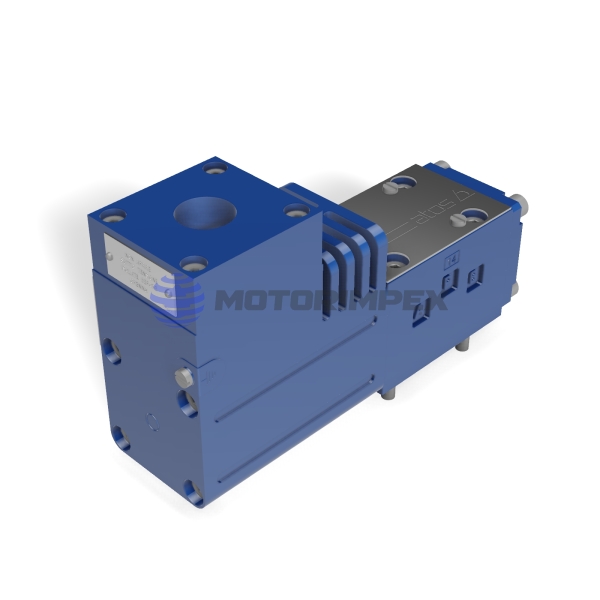

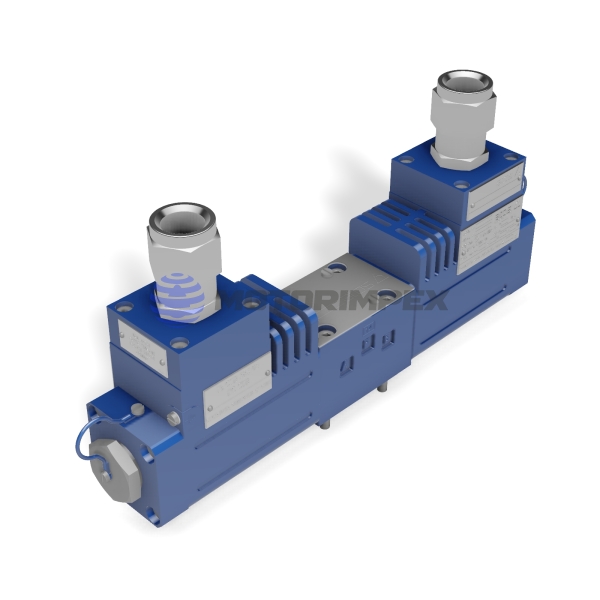

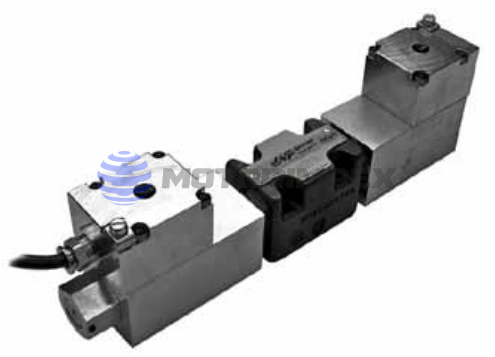

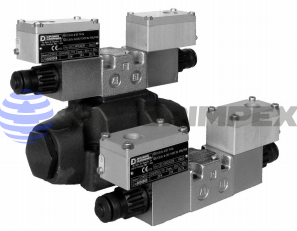

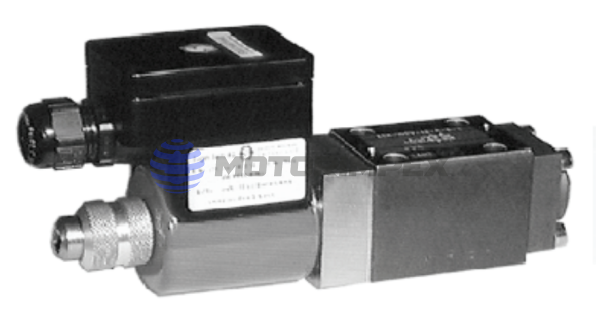

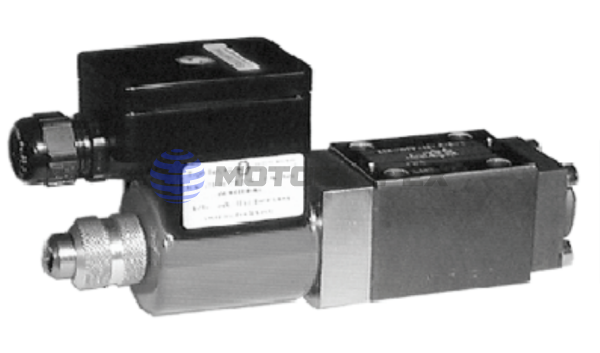

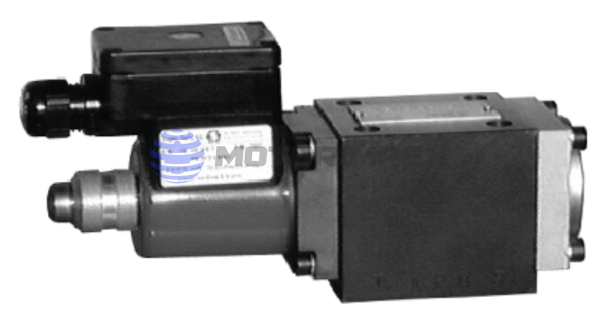

Spark-explosion-proof hydraulic valves

We are a leader in the supply of hydraulic distributors in Ukraine. We have the largest hydraulic warehouses in the country, and a large part of the product brands is represented exclusively by us.

A wide range of product models is always in stock to quickly meet customer needs. All products listed in the technical catalogs are available for order.

DN 6

maximum working pressure: 315 bar

maximum flow rate: 20 l/min

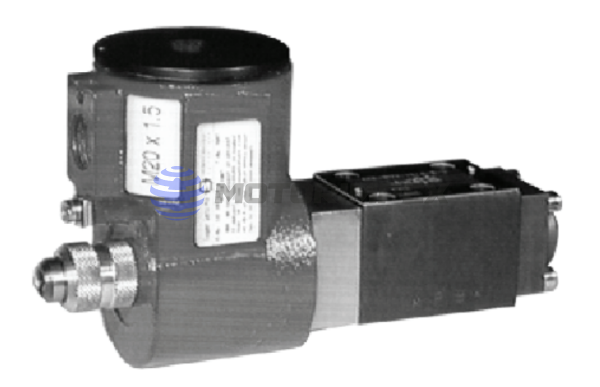

M22x1.5

2-way

maximum working pressure: 315 bar

maximum flow rate: 20 l/min

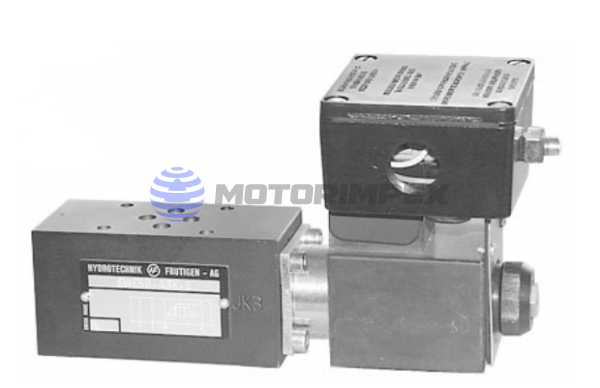

M22x1.5

2-way

maximum working pressure: 315 bar

maximum flow rate: 30 l/min

M33x2

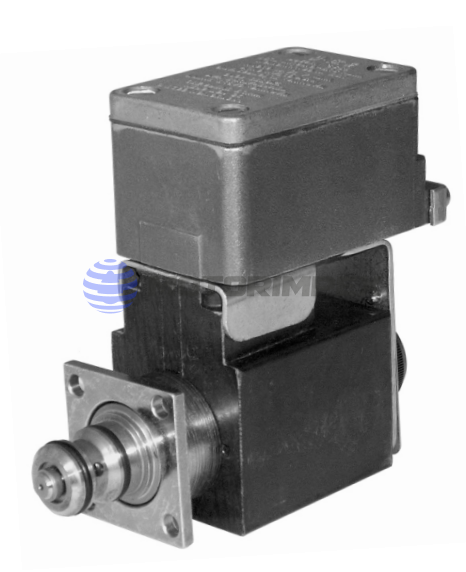

2-way

maximum working pressure: 315 bar

maximum flow rate: 60 l/min

Ø 20 mm

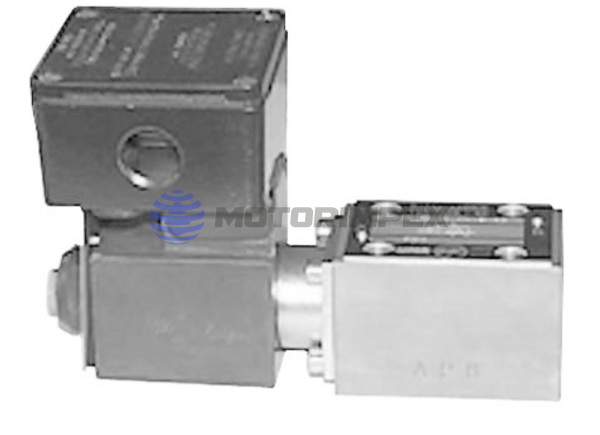

3-way

maximum working pressure: 315 bar

maximum flow rate: 1.3 l/min

M22x1.5

maximum working pressure: 315 bar

maximum flow rate: 20 l/min

DN 6–22

DN 6–32

with position sensor

DN 6

maximum working pressure: 350 bar

maximum flow rate: 60 l/min

DN 6–32

DN 6

maximum working pressure: 350 bar

maximum flow rate: 70 l/min

DN 6, 10, 16, 22

maximum working pressure: 350 bar

maximum flow rate: 700 l/min

up to 10 sections

maximum working pressure: 315 bar

maximum flow rate: 150 l/min

DN 4

maximum working pressure: 700 bar

maximum flow rate: 12 l/min

DN 6

maximum working pressure: 350 bar

maximum flow rate: 80 l/min

DN 6, 10, 16, 22, 32

maximum working pressure: 350 bar

maximum flow rate: 1100 l/min

DN 6

maximum working pressure: 160 bar

maximum flow rate: 18 l/min

DN 10

maximum working pressure: 315 bar

maximum flow rate: 90 l/min

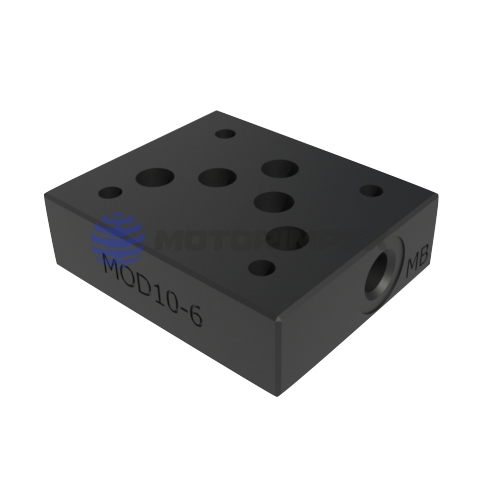

modular mounting

DN 6

maximum working pressure: 315 bar

maximum flow rate: 20 l/min

maximum working pressure: 315 bar

maximum flow rate: 20 l/min

maximum working pressure: 315 bar

maximum flow rate: 20 l/min

DN 6

maximum working pressure: 315 bar

maximum flow rate: 20 l/min

DN 6

maximum working pressure: 160 bar

maximum flow rate: 18 l/min

DN 6

maximum working pressure: 315 bar

maximum flow rate: 60 l/min

DN 10

maximum working pressure: 315 bar

maximum flow rate: 90 l/min

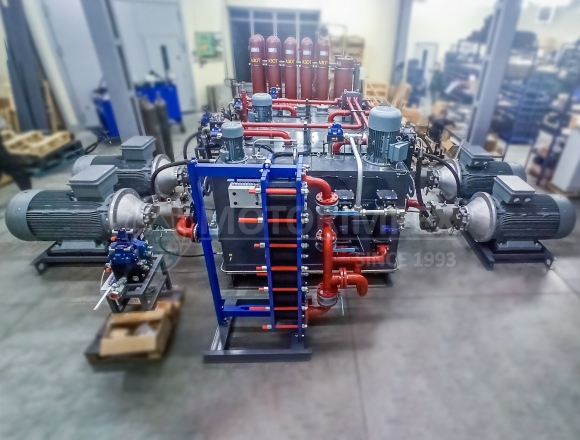

Category description

If in enterprises and industrial facilities the production process is associated with a risk of fire, to ensure safe working conditions it is necessary to buy explosion-proof hydraulic valves. They are used in underground mining workings, in units that operate in the vicinity of rapidly flammable substances (gaseous, in the form of steam and fog). This device is used to change the direction of flow of the working fluid in hydraulic systems.

The Motorimpex group of companies offers a wide range of explosion-proof hydraulic systems. We can select a mechanism in accordance with the specifics and dimensions of the structure.

Operating principle

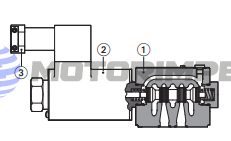

A spool is placed in the housing chamber, which closes the channels or connects them when moving. Motion The spool in the cavity takes place when voltage is applied to the coil by means of the intermediate plate. V the spool is returned to its original position by means of springs. The coil can be mounted at any angle relative to the electromagnet. Spark-explosion-proof hydraulic distributors can be operated manually mode, using a button: it is located in the sleeve of the spark-safe electromagnet. The spool is placed on the sleeve with electrical box. An intermediate plate is provided for the electrical connection. For protection from external influences there are O-rings, also necessary for fixing the coil by means of a screwed nut.

Type of connection to the hydraulic system

Spark-proof hydraulic valves in Ukraine can be mounted to the hydraulic system in the following ways:

- Butt joint, in which the side of the distributor and the mounting plate is joined;

- Threaded, into threaded holes;

- Screwed into the stove.

Buy protected hydraulic valves in Kharkov: advantages

What are the advantages of the decision to buy hydraulic distributors with protection in Ukraine?

- The presence of a special explosion-proof housing makes it possible to operate the mechanism in conditions of increased risk of sparking;

- The occurrence of an explosion inside the mechanism is prevented by limiting the compression and discharge effect;

- Magnets have passed industry standard tests in accordance with the system requirements that operate in explosive environments.

You can also order from us hydraulic cartridge distributors.

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

maximum continuous torque: 500 N∙m

for ZF trucks

maximum continuous torque: 300 N∙m