- Hydraulic equipment catalog

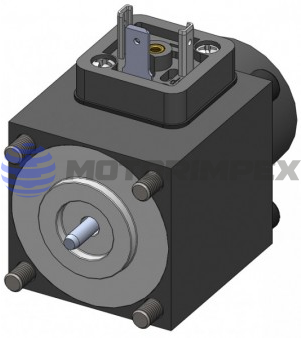

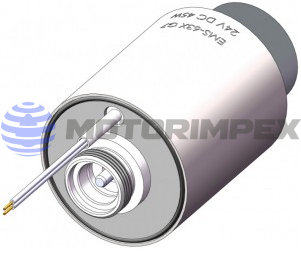

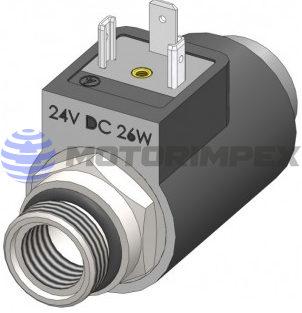

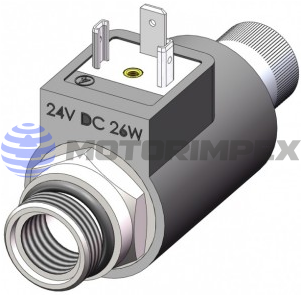

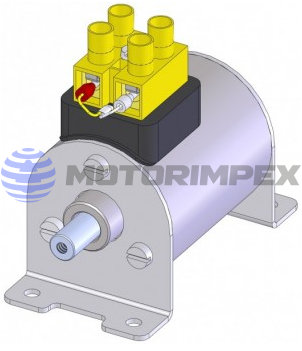

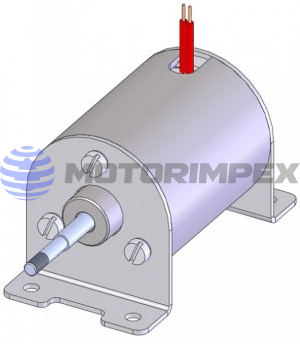

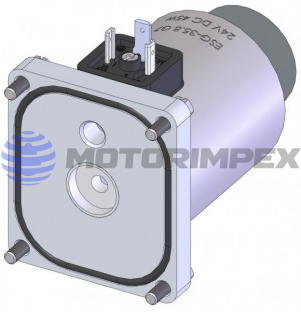

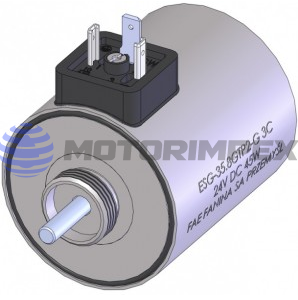

- Coils and Electromagnets

Coils and Electromagnets

We also supply coils and solenoids for hydraulic valves. Most product manufacturers are represented exclusively.

A wide selection of models is always in stock for quick supply. All nomenclature listed in the technical catalogs is available for order.

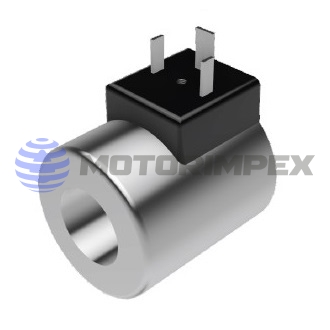

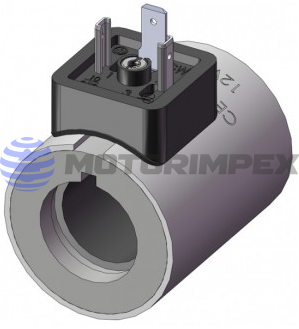

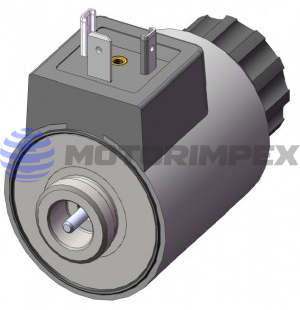

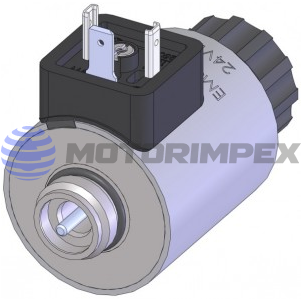

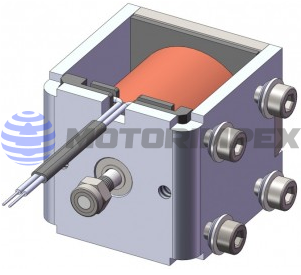

12, 24 VDC

110, 220 VAC

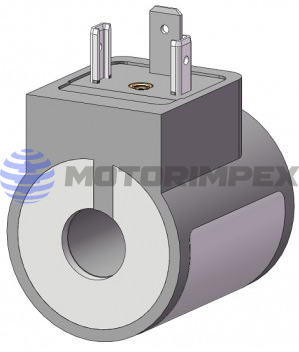

Ø int 23 mm

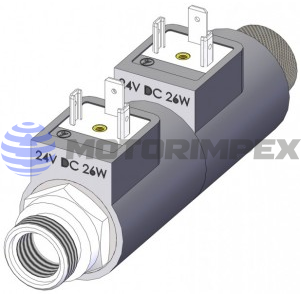

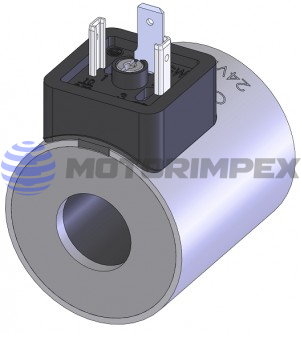

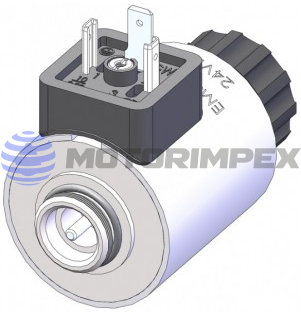

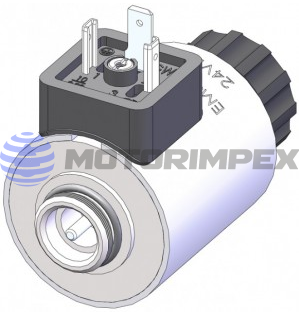

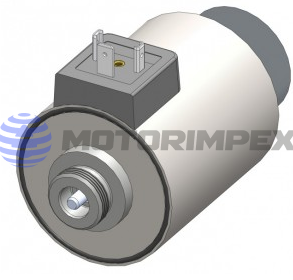

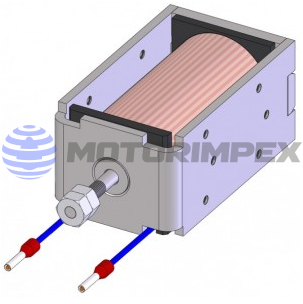

12, 24 VDC

110, 220 VAC

Ø int 31,6 mm

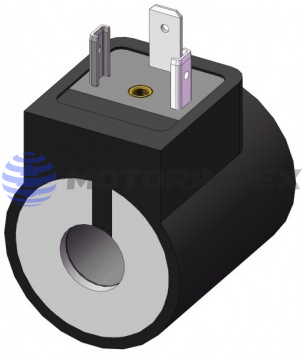

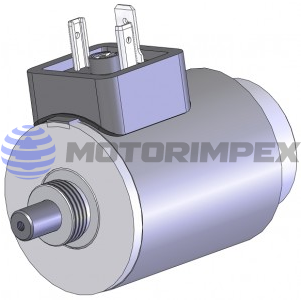

12, 24 VDC

24, 110, 220 VAC

Ø ext 13, 14, 16 mm

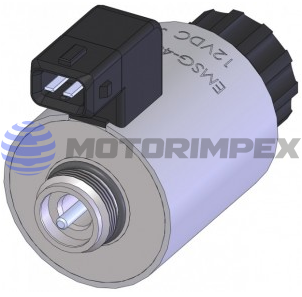

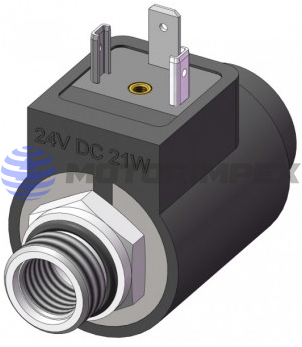

12-206 VDC

M22x1,5

12, 24, 96, 110, 206 VDC

7/8–14 UNF

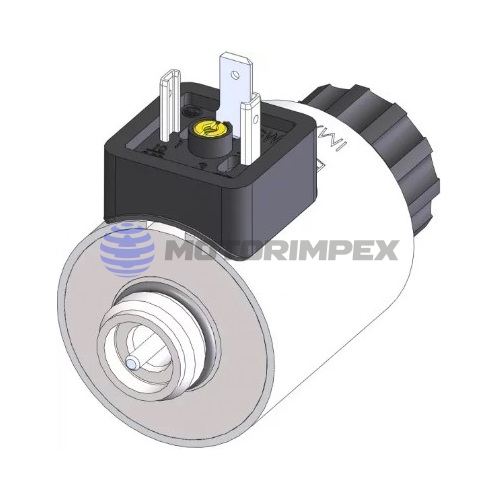

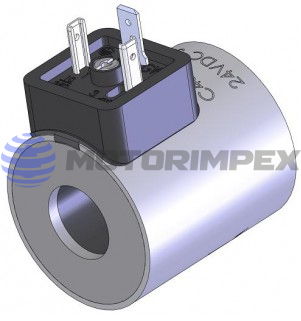

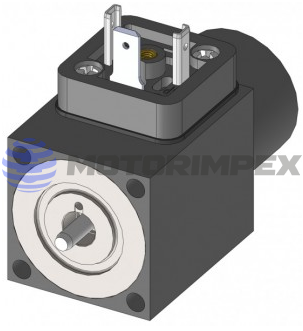

12, 24 VDC

110, 220 VAC

Ø int 44 mm

12, 24, 96, 110, 206 VDC

Ø ext 16 mm

12, 21, 24, 42, 48, 60, 96, 110, 125, 206, 220 VDC

Ø ext 23 mm

12, 24, 42, 48, 60, 96, 110, 125, 206, 220 VDC

Ø ext 31.6mm

12, 24 VDC

Ø ext 19, 21, 22, 23 mm

24, 48, 72, 110 VDC

Ø ext 26mm

12, 24, 107, 110, 196 VDC

12, 24, 96, 110, 206 VDC

M22x1.5

12, 24, 96, 110, 206 VDC

M22x1.5

12, 21, 24, 48, 60, 96, 110, 125, 206, 220 VDC

M20x1

12, 21, 24, 42, 48, 60, 96, 110, 125, 206, 220 VDC

M20x1

12, 24, 42, 48, 60, 96, 110, 125, 206, 220 VDC

M26x1.5

12, 24, 196 VDC

M18x1.5

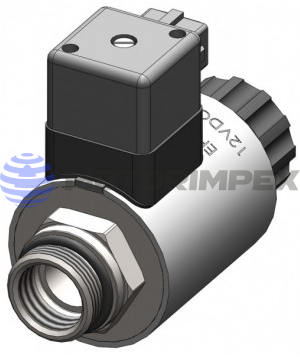

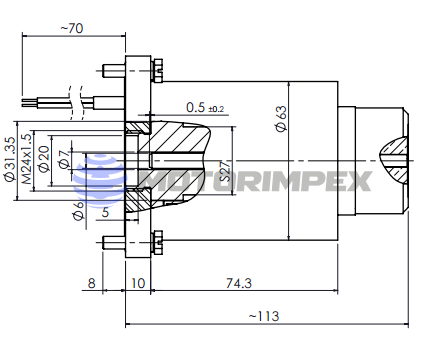

10.5–14.5 VDC

M24x1.5/M19x1

12, 24, 110 VDC

24, 110, 220 VAC

Ø ext 13.2 mm

12 VDC

Ø ext 8.7 mm

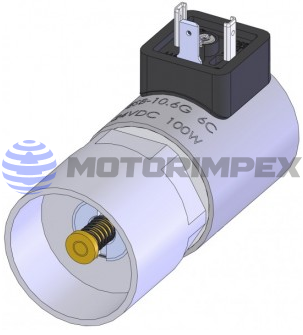

12, 24, 42, 48, 96, 110, 125, 206, 220 VDC

M24x1.5

12, 24, 110 VDC

M24x1.5

24, 110 VDC

Ø ext 18 mm

12, 24 VDC

115, 230 VAC

Ø ext 18mm

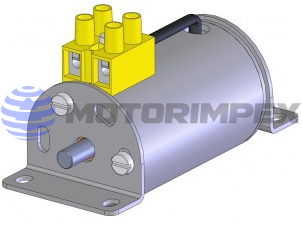

Category description

Coils and electromagnets

Electromagnets are determined by several characteristics, the main of which is the formation of magnetic flux.

Electromagnets type

- neutral — create a magnetic force that does not depend on the direction of the electric current, but only on its strength

- polarized — two streams are used simultaneously (working and polarizing). The functioning of such electromagnets depends on both the directionality and the strength of the current

- AC electromagnets — the winding is powered from an AC source. They are used mainly in large mechanisms and household appliances.

Features of electromagnet characteristscs and their application

Electromagnetic hydraulic valves and directional control valves.

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

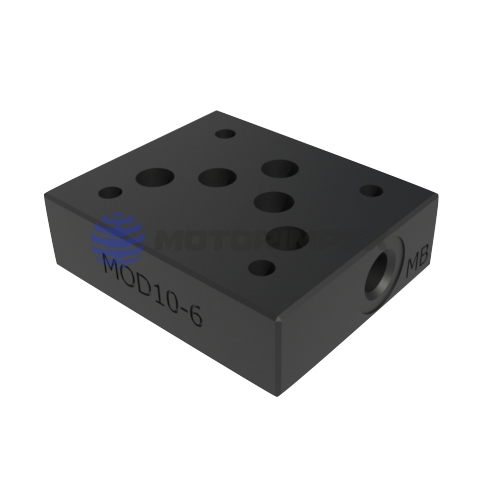

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

maximum continuous torque: 500 N∙m

for ZF trucks

maximum continuous torque: 300 N∙m