- Hydraulic equipment catalog

- Steering units

Steering units

Trading company "Motorimpex" is the largest supplier of steering units in Ukraine. Manufacturers are represented exclusively.

Most models are in stock for quick supply. All products from the technical catalogs are available for order.

maximum displacement: 400 cm3/rev

maximum displacement: 400 cm3/rev

maximum displacement: 990 cm3/rev

maximum displacement: 500 cm3/rev

maximum displacement: 145 cm3/rev

maximum displacement: 200 cm3/rev

maximum displacement: 100 cm3/rev

maximum displacement: 793 cm3/rev

maximum displacement: 125 cm3/rev

maximum displacement: 100 cm3/rev

maximum displacement: 200 (500) cm3/rev

maximum displacement: 500 cm3/rev

maximum displacement: 250 cm3/rev

maximum displacement: 250 cm3/rev

eightfold boost of torque

maximum displacement: 625 cm3/rev

maximum displacement: 125 cm3/rev

maximum displacement: 990 cm3/rev

maximum displacement: 100 cm3/rev

maximum displacement: 100 cm3/rev

maximum displacement: 200 cm3/rev

maximum displacement: 400 cm3/rev

maximum displacement: 400 cm3/rev

maximum displacement: 160 cm3/rev

Category description

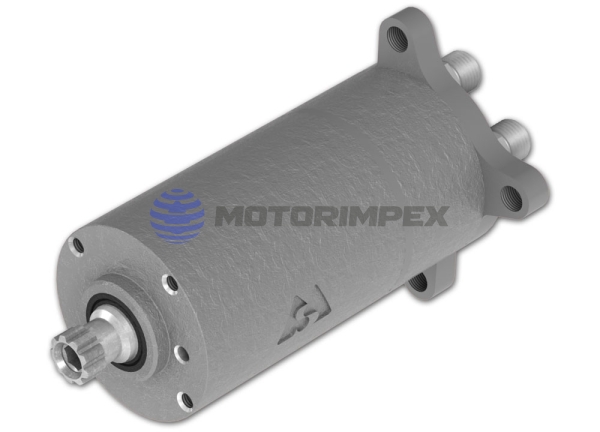

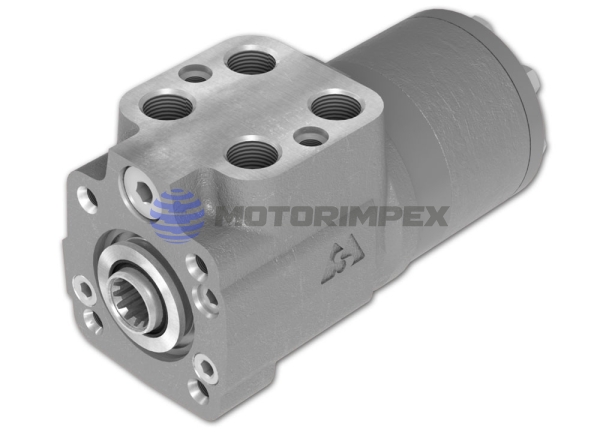

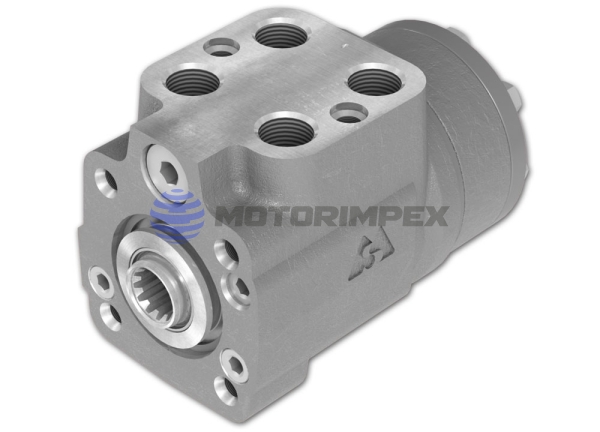

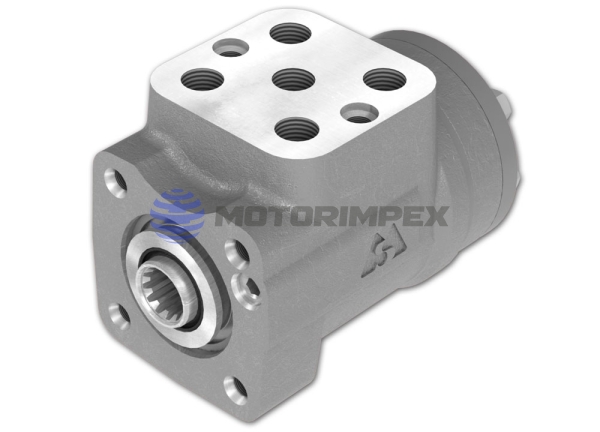

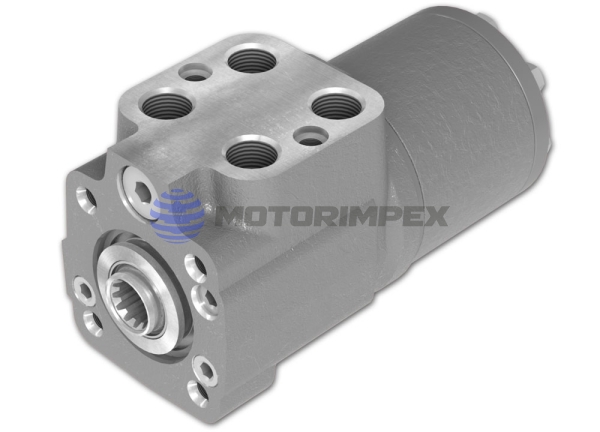

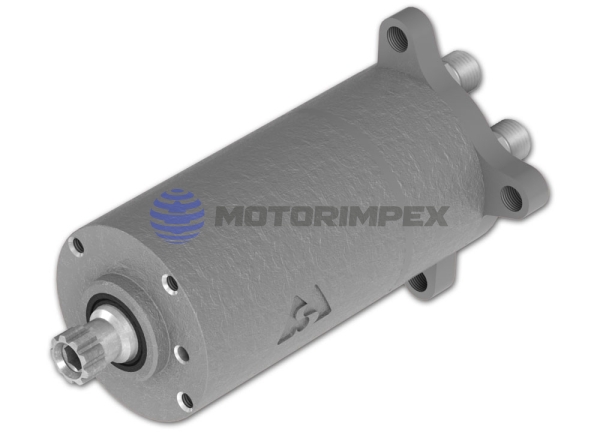

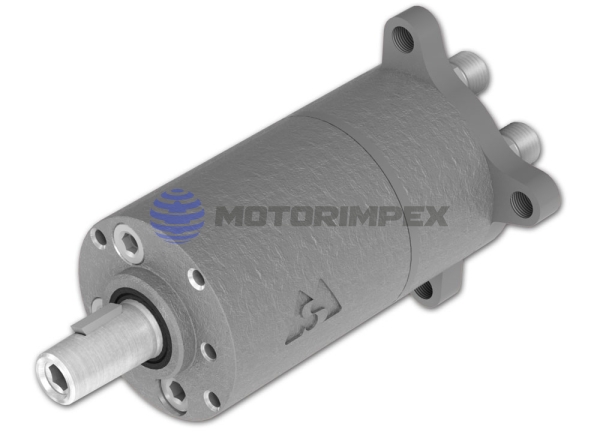

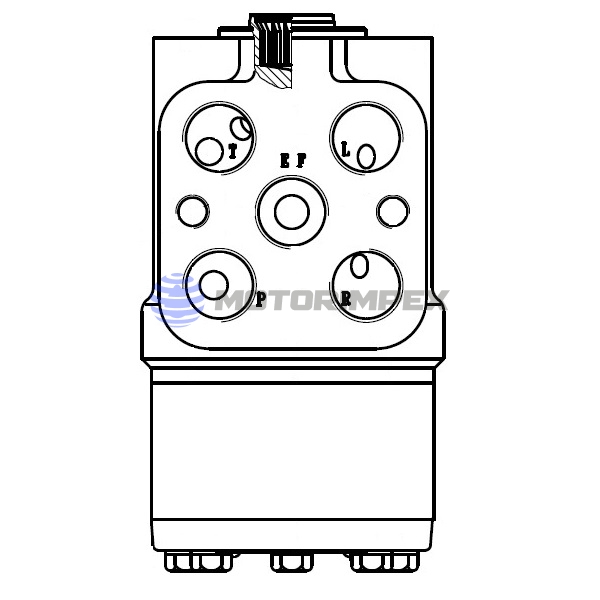

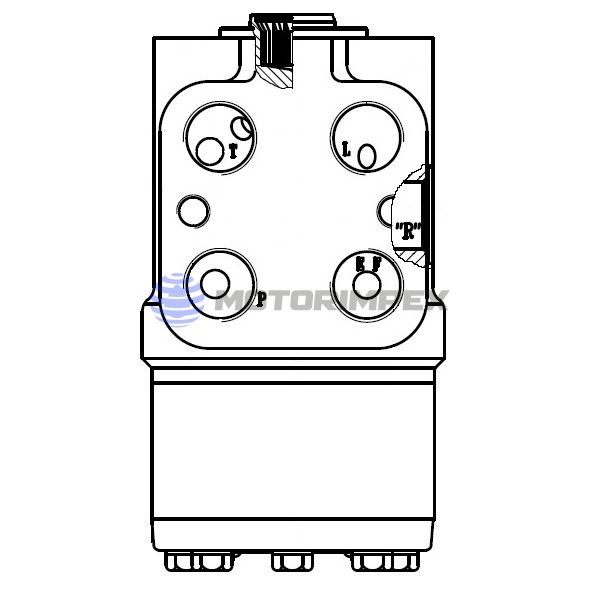

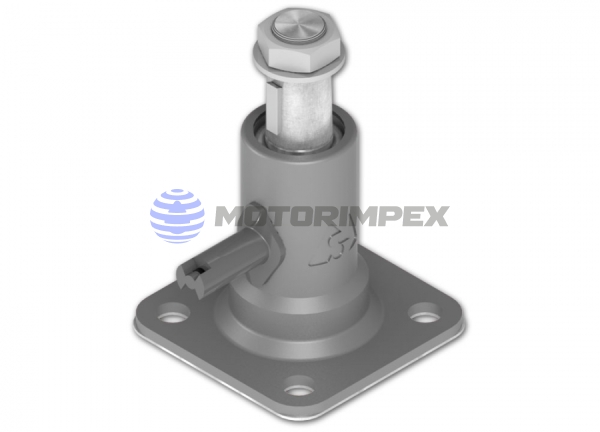

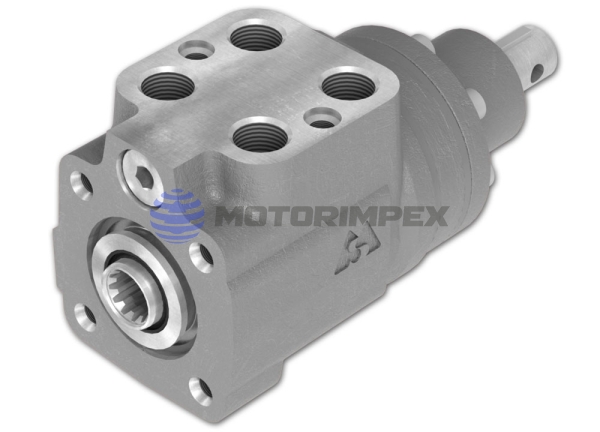

Steering unit

Pump with dispenser – this is a hydraulic unit that works together with a gear pump and a hydraulic cylinder. The direct purpose of the metering pump is to proportionally apply pressure to one cavity of the cylinder or to another, depending on the rotation of the wheels.

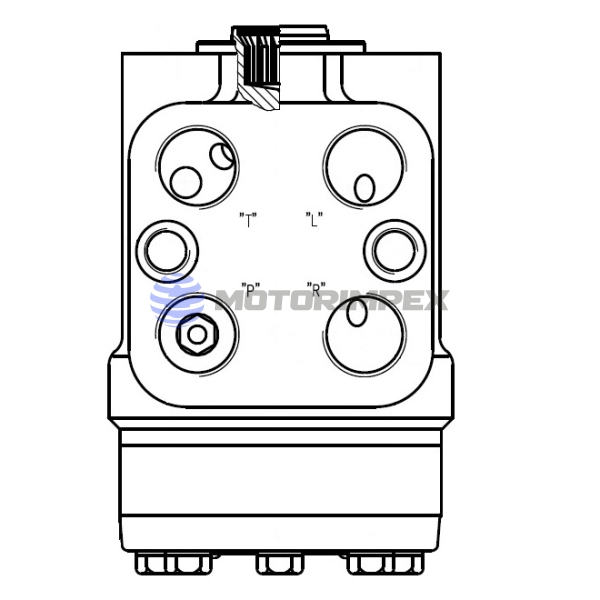

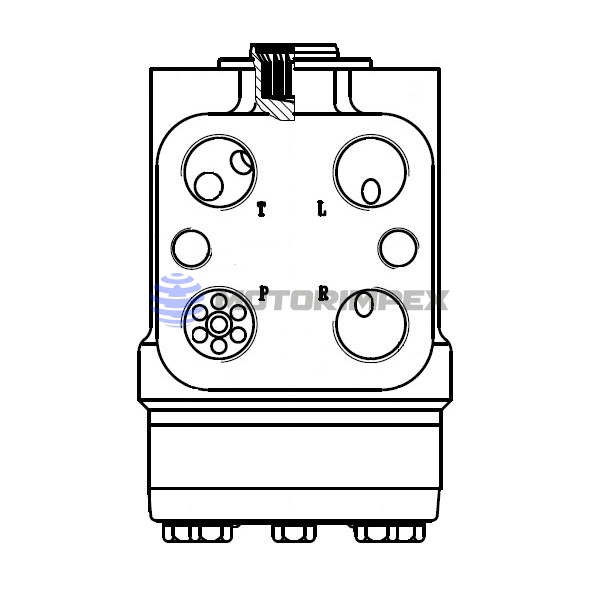

Metering pump device

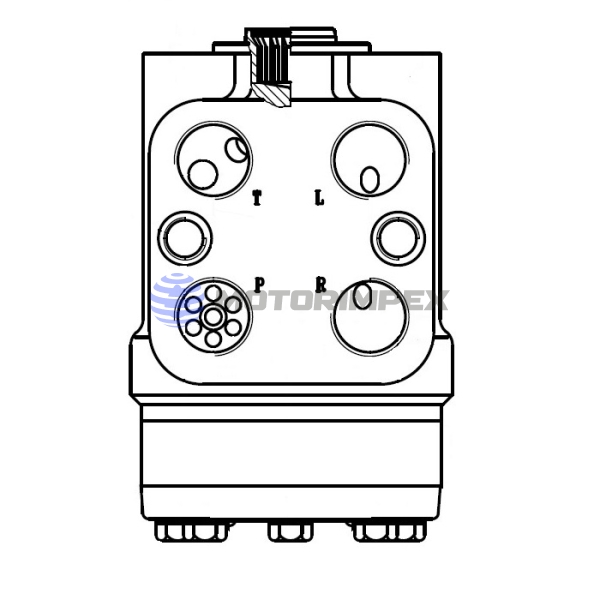

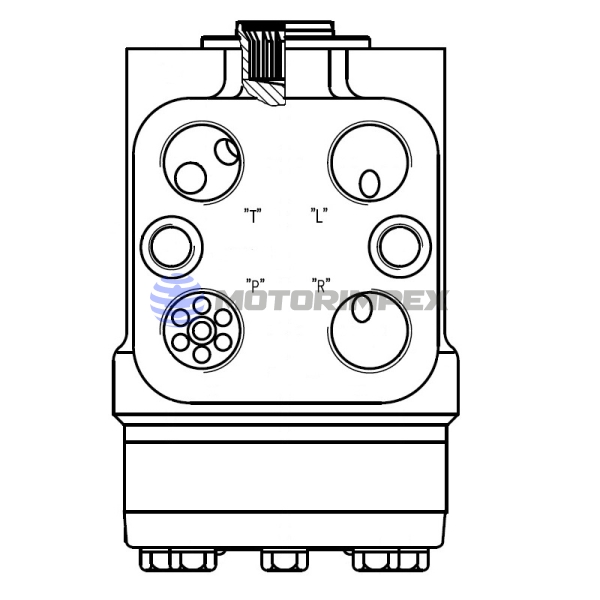

The design of the hydraulic dispenser includes:

- Gerotor-type pumping unit, consisting of two gears.

- The distributor, which includes the spool, drive shaft and sleeve. It directs the fluid supply to the cylinder.

- Two anti-shock valves to prevent water hammer in the cylinders.

- Relief valve – it regulates a constant pressure in the metering pump and prevents overpressure in the supply. It can be built into the pump and screwed to it in the form of a valve block or taken out separately, being in the hydraulic system (such a valve is called a "portioner").

- Two vacuum valves, which are needed to regulate the pressure in both cavities of the cylinder in the event of an anti-shock valve.

The principle of the steering unit

When the steering column and spool are in neutral, pressure flows from the supply to the drain. The rotation of the steering wheel causes the spool to turn and open the grooves in the metering pump housing itself. They block the drain and supply liquid directly to the pumping unit, which drives the internal gear.

In turn, she turns the sleeve, thereby opening the grooves to the entrance to the cylinder itself. Under pressure, the grooves supply liquid in portions to the cylinder cavity, after which the rod exits and the wheels turn. When the steering wheel returns to the neutral position again, the grooves are blocked by the spool and the fluid flows back to the drain.

Are you planning to buy a steering unit for pumping various types of working fluids? We offer a wide range of hydrostatic steering for tractors. Here you will find hydraulic cylinders, steering units and other devices at reasonable prices with guaranteed quality.

We deliver to any point in Ukraine in the optimal time. Place your order right now!

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

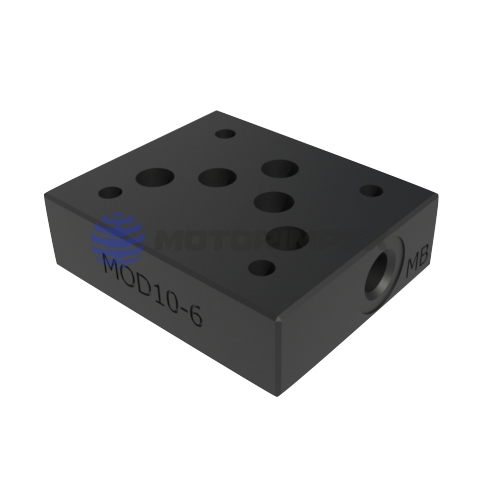

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

for ZF trucks

maximum continuous torque: 300 N∙m

G1/8, М5х0,8, G1/4, G3/8, G1/2

scheme: 5/2, 5/3

max. number of cycles per sec.: 5

response time: 0,05 sec