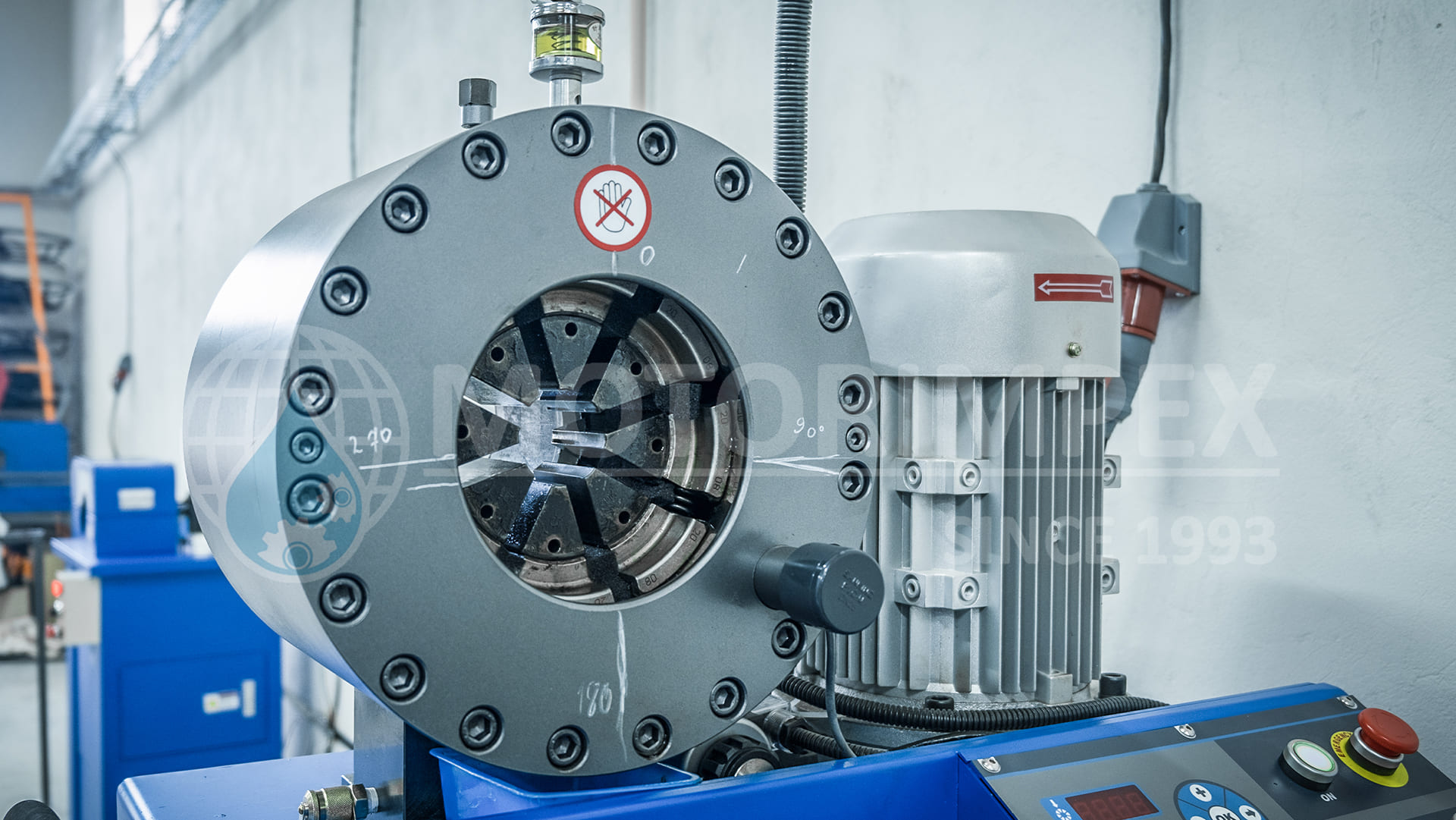

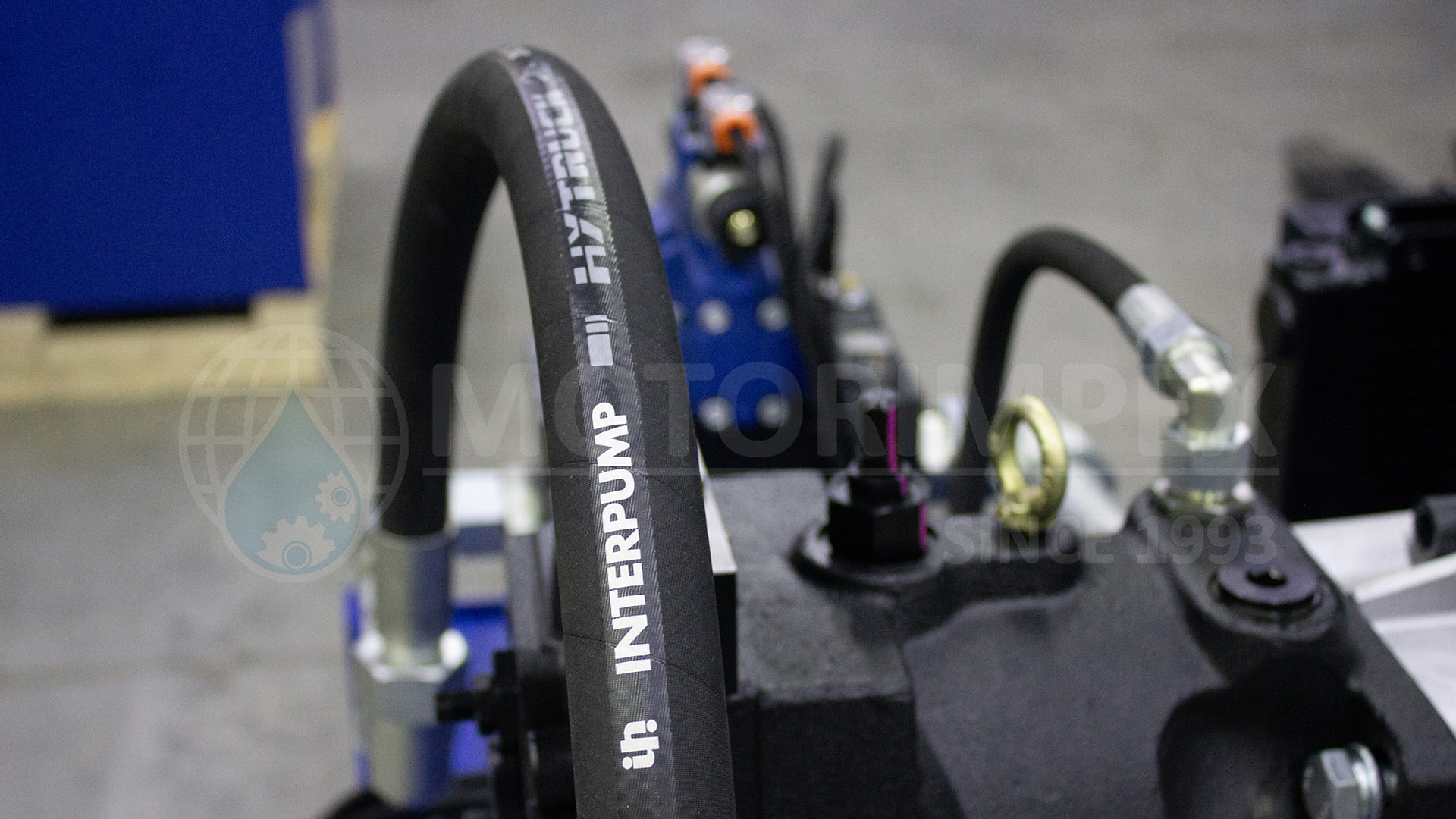

- Production of high-pressure hoses

- High-pressure hydraulic hoses

High-pressure hydraulic hoses

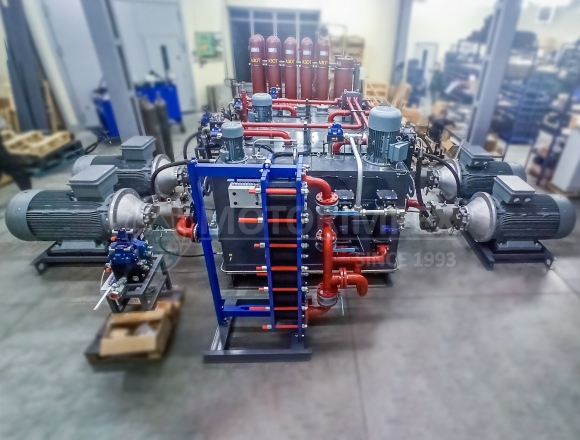

Trading company "Motorimpex" is one of the largest suppliers of high-pressure hydraulic hoses in Ukraine. Most product manufacturers are represented exclusively.

A significant portion of hose types is constantly in stock. All nomenclature presented in the technical catalogs is available for order.

Category description

High-pressure hoses for hydraulics: structure and types

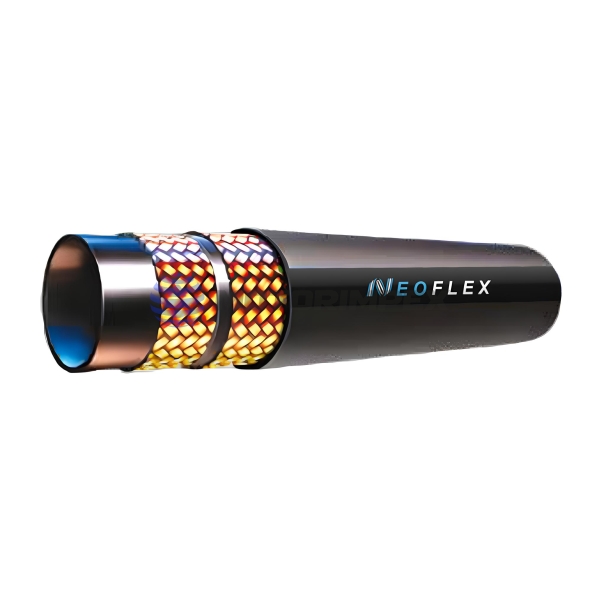

High-pressure hoses or high-pressure hoses are flexible pipelines used for hydraulic systems. Oils, liquids and emulsions are conveyed under high pressure. The hose design is a pair or several rubber tubes, which are placed one inside the other by means of reinforced coils or braids made of metal.

HPHs are used in different structures of hydromechanisms and machines:

- construction, road machinery;

- lifting and transportation equipments;

- logging machines;

- agricultural, automotive and tractor equipments;

- industrial machinery.

Also this type of units helps to transport liquid fuels, emulsions, motor and hydraulic oils, greases. The main advantages of using high-pressure hoses for hydraulics are:

- lightness and extreme flexibility even in conditions of low ambient temperature;

- the structure of the hose allows its use even if several layers are broken or damaged;

- the hose components are not subject to obsolescence.

What is the construction of high-pressure hoses for hydraulics

The composite hose is based on inner and outer support spirals made of galvanized steel. Aluminum, stainless steel or polypropylene encased steel can also serve as a material for manufacturing such spirals. Film and thermoplastic material are laid between the spirals in several layers. The hose parts hold the walls of the hose and also ensure their integrity during suction.

Outer spiral – required to bond the structural layers of the hose, as well as to ensure the resistance of the outer layer to mechanical damage and abrasion. As standard, the outer coating is made of fabric-based PVC, which makes the hose more resistant to internal pressure. For hose recognition, these coatings differ in color – for example, for light oil products, a blue hose with a yellow stripe is used.

The inner layer is necessary for the tightness of the hose. This layer can be a film of polyamide, polypropylene or fluoroplastic (PTFE). The combination of these materials helps to strengthen the specified parameters of the hose – pressure, operating temperature and chemical resistance.

The fitting is the end element of the hose and has a special profile. It is made of steel or aluminum and is used to attach the hose to flanges or quick couplings.

How to choose and buy a high-pressure hose

All high-pressure hoses can be divided into special and universal. Among the latter, the following types are distinguished:

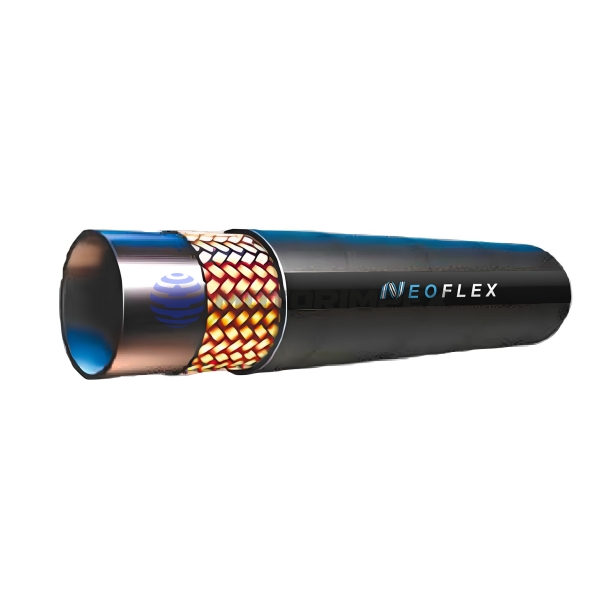

- EN 853 braided hoses are the most common high-pressure hydraulic hoses. They are designed for an average pressure of up to 400 bar and are reinforced with one or two steel braids. The main representatives in this category are 1SN, 2SN and 2SC, where the number indicates the number of braids.

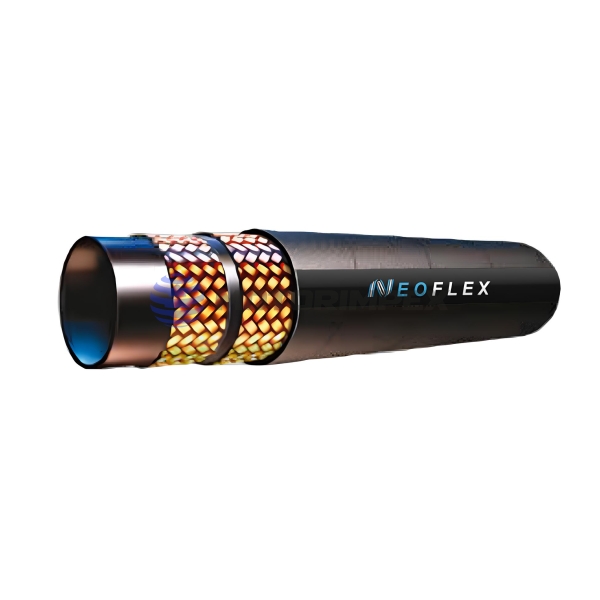

- Sleeves with EN 856 coiling are less popular, but an important element of hydraulic systems where high pressure is used. The most common representatives are: 4SP – 4 spiral wire coils made of steel – for medium pressure, 4SN – 4 wire coils of increased strength – withstands high pressures, R12 – heavy hose with 4 coils – for continuous work at medium pressure and high temperatures, multi-spiral hose R13 and R15 with six coils for heavy working conditions at the highest temperatures and pressures. Characterized by increased service life.

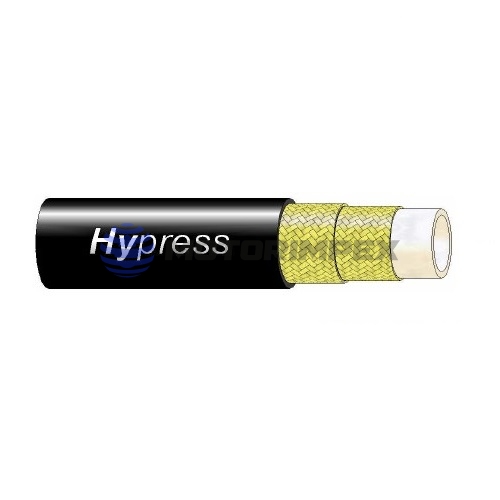

- Special HPHs – PTFE, as well as hoses for operation at elevated temperatures. These are Teflon hoses, which are most often used in chemical and food production. Their peculiarity is that the inner layer is made of fluoroplastic tubing, and the outer layer is reinforced and includes a steel braid in one or more layers. Due to this, it is durable and chemical resistant, withstands temperature from -60℃ to +260℃ and pressure up to 225 Bar.

If you need to order a high-pressure hydraulic hose at a favorable price wholesale or retail – go to the site of the company Motorimpex. We sell hydraulic components and provide warranty and post-warranty service. This will provide you with confidence that our hydraulic products will serve for a long time and protect the work of the entire hydraulic system from unexpected breakdowns and failures.

Want to buy a high-pressure hose in Ukraine? Check out our catalog right now!

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

for ZF trucks

maximum continuous torque: 300 N∙m

G1/8, М5х0,8, G1/4, G3/8, G1/2

scheme: 5/2, 5/3

max. number of cycles per sec.: 5

response time: 0,05 sec