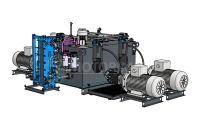

- Hydraulic equipment catalog

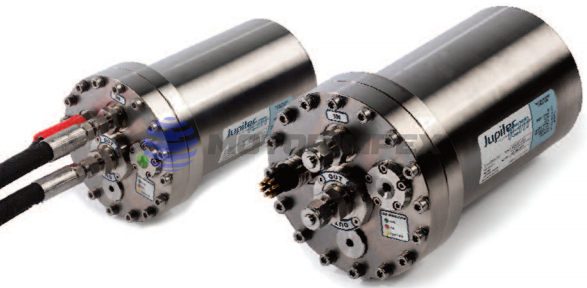

- Hydraulic system diagnostics devices

Hydraulic system diagnostics devices

We are a leader in the supply of fluid condition monitoring systems in Ukraine. A large number of manufacturers are represented exclusively.

A wide range of models is constantly in stock for quick supply. All products listed in the technical catalogs are available for order.

sensitivity: 4, 6, 14, 21, 25, 38, 50, 70 µm

monitoring time: programmable by end user

flow measurement error: ± 3%

maximum working pressure: 420 bar

sensitivity: 4, 6, 14, 21, 25, 38, 50, 70 µm

monitoring time: 10–3600 s

flow measurement error: ± 0,5% (4, 6, 14 µm), ± 1% (21, 25, 38, 50, 70 µm)

maximum working pressure: 420 bar

sensitivity 4, 6, 14, 21, 25, 38, 50, 70 µm

monitoring time: 10–3600 s

flow measurement error: ± 0.5% (4, 6, 14 µm), ± 1% (21, 25, 38, 50, 70 µm)

maximum working pressure: 400 bar

sensitivity: 4, 6, 14, 21, 25, 38, 50, 70 µm

monitoring time: 170–3600 s

flow measurement error: ± 3%

maximum working pressure: 400 bar

sensitivity: 4, 6, 14, 21, 25, 38, 50, 68 µm

monitoring time: 90–3600 s

flow measurement error: ± 3%

maximum working pressure: 400 bar

sensitivity: 4, 6, 14, 21, 25, 38, 50, 70 µm

monitoring time: 10–3600 s

flow measurement error: ± 0.5% (4, 6, 14 um), ± 1% (21, 25, 38, 50, 70 µm)

maximum working pressure: 400 bar

sensitivity: 4, 6, 14, 21, 25, 38, 50, 70 µm

flow measurement error: ± 0.5% (4, 6, 14 µm), ± 1% (21, 25, 38, 50, 70 µm)

maximum working pressure: 400 bar

sensitivity: 4, 6, 14, 21 µm

flow measurement error: ± 0.5%

maximum working pressure: 345 bar

sensitivity: 4, 4.6, 6.4, 10, 14, 21, 37 µm

flow measurement error: ± 1%

maximum working pressure: 420 bar

sensitivity: 4, 4.6, 6.4, 10, 14, 21, 37 µm

flow measurement error: ± 1%

maximum working pressure: 40 bar

sensitivity: 4, 6, 14 µm

flow measurement error: ± 1%

maximum working pressure: 35 bar

sensitivity: 4, 6, 14 µm

flow measurement error: ± 1%

maximum working pressure: 50 bar

sensitivity: 4, 6, 14, 21, 37 µm

flow measurement error: ± 1%

maximum working pressure: 50 bar

sensitivity: 2–50 µm

flow measurement error: ± 0.5%

maximum working pressure: 350 bar

sensitivity: 2–100 µm

flow measurement error: ± 0.5%

maximum working pressure: 350 bar

sensitivity: 4, 5, 6, 14, 15, 21, 25 µm

maximum working pressure: 120 bar

sensitivity: 2–50 µm

maximum working pressure: 120 bar

sensitivity: 4–100 µm

monitoring time: 75 s

with indicator of contamination CS and the water content sensor AS

sensitivity: 4, 6, 14, 21 µm

flow measurement error: ± 1%

maximum working pressure: 420 bar

sensitivity: 4, 6, 14, 21 µm

flow measurement error: ± 0.5%

maximum working pressure: 350 bar

sensitivity: 2, 4, 5, 6, 14, 15, 21, 25, 50 µm

flow measurement error: ± 0.5%

maximum working pressure: 350 bar

G3/4

flow measurement error: ± 3%

maximum working pressure: 50 bar

G3/4

flow measurement error: ± 3%

maximum working pressure: 50 bar

G3/8

flow measurement error: ± 3%

maximum working pressure: 50 bar

flow measurement error: ± 2%

temperature measuring range: -20–120 °C

maximum working pressure: 10 bar

G3/8

flow measurement error: ± 3%

maximum working pressure: 50 bar

flow measurement error: ± 2%

maximum working pressure: 10 bar

viscosity measurement range: 6–1200 mm2/s

temperature measuring range: -40–130 °C

sensitivity 70, 100, 200 µm

maximum flow rate: 200 l/min

maximum working pressure: 20 bar

sensitivity: 200 µm

maximum flow rate: 50 l/min

maximum working pressure: 20 bar

sensitivity: 260 µm

maximum flow rate: 110 l/min

maximum working pressure: 20 bar

sensitivity: 350 µm

maximum flow rate: 320 l/min

maximum working pressure: 20 bar

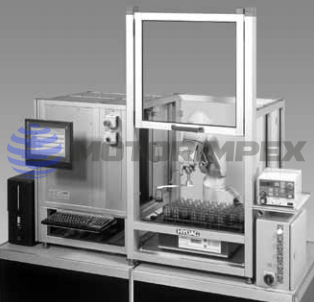

for using with mobile monitoring system "FCU 8000"

for CS1000 purity grade sensors, moisture sensors and AS1000 metal particles content sensors MCS1000

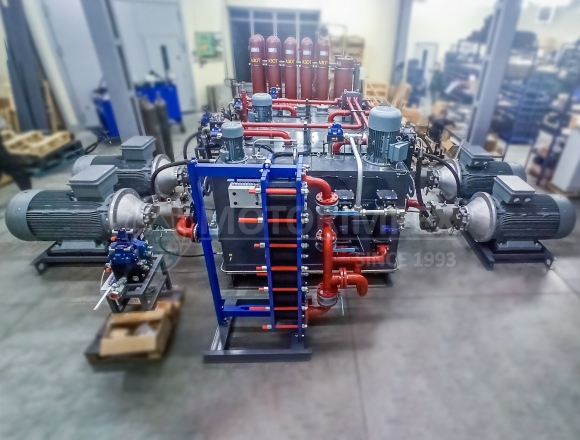

Category description

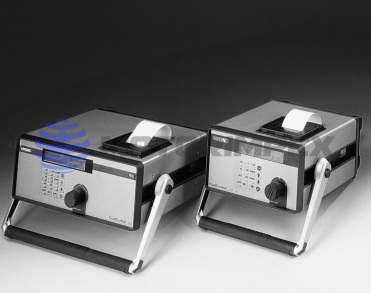

Working fluid condition monitoring systems

Wide range of systems for monitoring the condition of the working fluid, which our company offers, guarantees comprehensive information to maintain all the optimal parameters of hydraulic equipment throughout the entire operating period.

Application of working fluid condition monitoring systems

Using high-quality working fluids is the main condition for ensuring the operability of hydraulic equipment, for the smooth operation of which it is recommended to constantly monitor the parameters of the working fluid.Using modern working fluid condition monitoring systems can prevent your hydraulic system for breaking, which can appear insufficient concentration or poor-quality composition of the working fluid.

On our website you can familiarize with technic documentation and order:

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

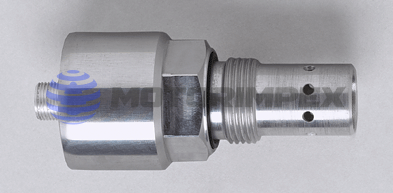

G3/8

maximum working pressure: 350 bar

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

for ZF trucks

maximum continuous torque: 300 N∙m

G1/8, М5х0,8, G1/4, G3/8, G1/2

scheme: 5/2, 5/3

max. number of cycles per sec.: 5

response time: 0,05 sec