- Production of hydraulics

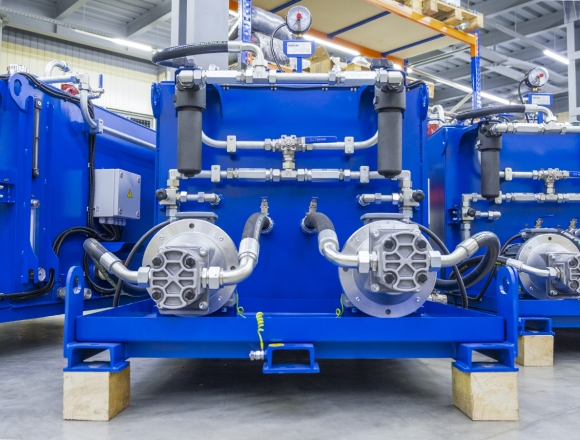

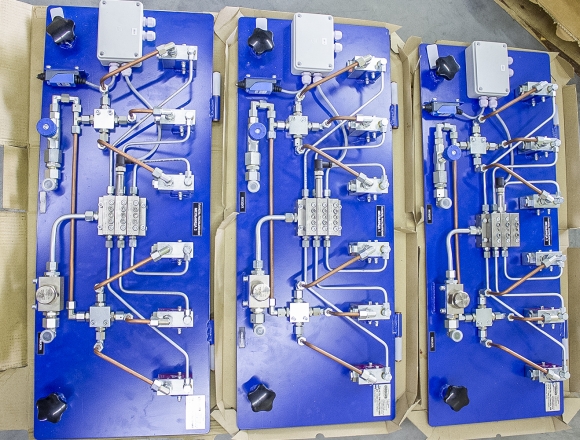

- Lubrication systems according to individual tasks

- Lubrication systems of 2277 series for open gear transmission

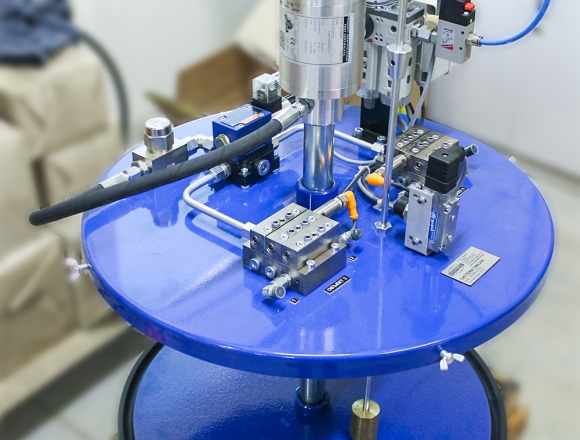

Open Gear Spray Lubrication System.

Gear spray is popular in cement plants, mining, Iron Ore crushers, kilns, and any external gear drive usually with a dry sump.

Pneumatic drive piston pumps manufactured by the company Dropsa (Italy) are installed for supplying oil. All equipment is mounted in a hinged cabinet: cyclone dryer and air preparation units, a 40-liter tank, main and backup pumps, which allows to make emergency repairs without stopping the system. Switching between pumps takes place in semi-automatic mode — just turn the ball valve to the required position. The progressive divider with an inductive cycle sensor of the Dropsa company allows to set the exact flow of lubricant and monitor emergency situations.

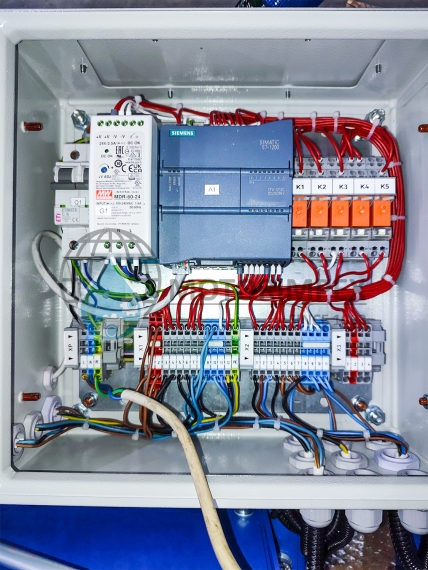

The control system based on the Siemens S7-1200 controller and the HMI panel of Weintek allows to make fully control the operation of all units and aggregates, the directions of air and lubricant movement, thanks to an intuitive mnemonic diagramm. The state of the system at a current moment of time can be easily determined by the indicators of the signal column. The generator of the air-lubricant mixture based on the oil-air divider manufactured by Dropsa and the panel of 8 sprayers is installed directly on the protectiv casing of the gear transmission, which requires the mounting of only two lines between the lubrication system and the gear — the air line and the oil line.

We design and manufacture customized lubrication systems for various industries to fit your equipment. Contact us for technical advice or to place an order.

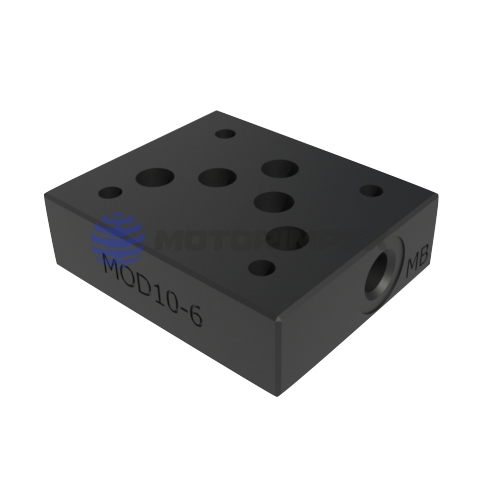

Associated components

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

DN 10

G1/4

maximum working pressure: 350 bar

maximum flow rate: 120 l/min

maximum continuous torque: 500 N∙m

for ZF trucks

maximum continuous torque: 300 N∙m

-

What payment methods do you offer?

We offer Bank transfer: available for legal entities and individual entrepreneurs. After placing an order, you will receive an invoice that can be paid at a bank or through your bank account.

-

Can I pick up my order myself?

Yes, you can pick up your order from our warehouse by prior arrangement. For details on self-pickup, please contact our engineers.

-

How quickly will I receive my order?

Delivery within Ukraine usually takes 1 to 3 business days, depending on your location. Orders placed before 3:00 PM are shipped the same day. International delivery terms are discussed individually.

-

Can I return or exchange a product?

Yes, you can return or exchange a product of proper quality within 14 days of receipt, provided that:

- The product has not been used and shows no signs of operation.

- The original packaging and all components are intact.

- All product labels and markings are preserved.

-

What is the warranty period for the products?

The warranty for all listed products is 12 months.