- Production of hydraulics

- Hydraulic manifolds

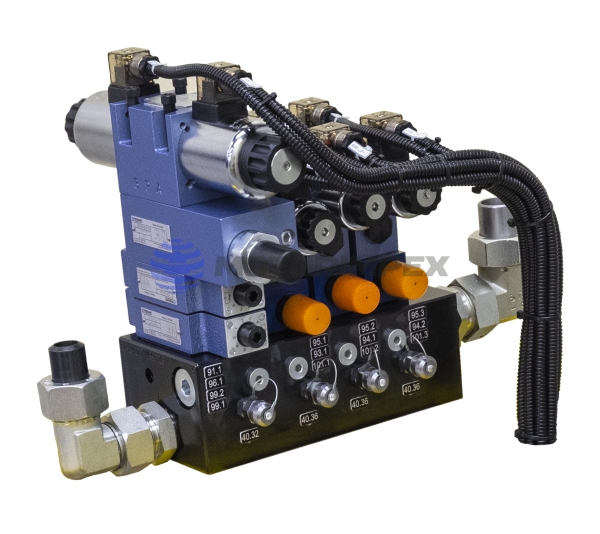

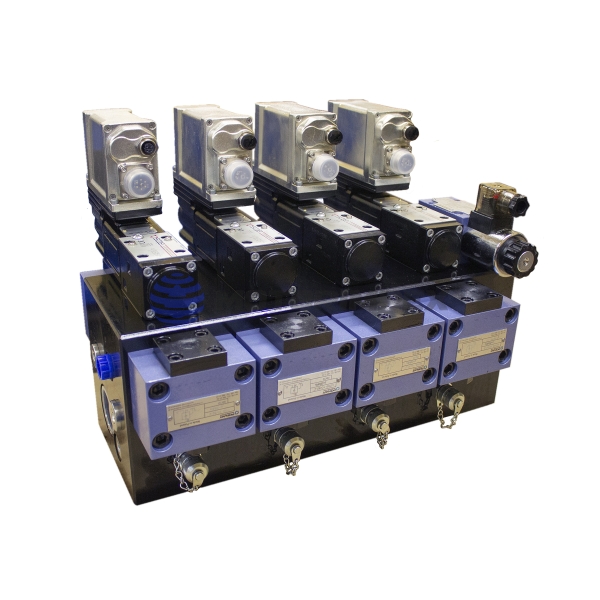

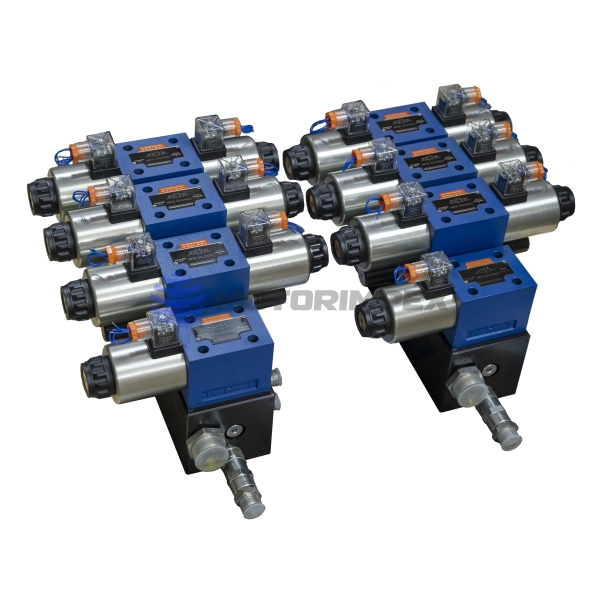

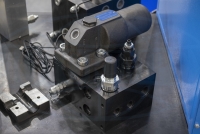

Production of Hydraulic manifolds by Motorimpex

"Motorimpex" Production Enterprise designs and manufactures hydraulic manifolds, adapting them to specific customer requirements. The main purpose of using manifolds in hydraulic systems is to provide more efficient control of working fluid flows and at the same time simplify the design of hydraulic channels.

The manifold's base – the mounting plate – is milled on high-precision "Haas" machines. The components included in the hydraulic manifold are supplied by us from leading global hydraulic brands.

maximum working pressure: 350 bar

maximum flow rate: 160 l/min

maximum working pressure: 350 bar

maximum flow rate: 250 l/min

maximum working pressure: 350 bar

maximum flow rate: 100 l/min

maximum working pressure: 350 bar

maximum flow rate: 160 l/min

maximum working pressure: 500 bar

maximum flow rate: 100 l/min

Category description

Order the production of Hydraulic manifolds — Design and implementation by "Motorimpex"

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum torque: 2500 N∙m

maximum speed: 900 rpm

maximum power: 22 kW

maximum displacement: 398 cm3/rev

maximum working pressure: 450 bar

maximum torque: 4770 N∙m

maximum speed: 700 rpm

maximum power: 50 kW

maximum displacement: 750 cm3/rev

maximum working pressure: 450 bar

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

G1/8, М5х0,8, G1/4, G3/8, G1/2

scheme: 5/2, 5/3

max. number of cycles per sec.: 5

response time: 0,05 sec