- Hydraulic equipment catalog

- Working fluid cleaning systems

Working fluid cleaning systems

We also supply hydraulic fluid cleaning systems. All products listed in the technical catalogs are available for order.

self-cleaning

rotation speed: 9600 rev/min

motor power: 3 kW

weight: 190 kg

self-cleaning

rotation speed: 8500 rev/min

motor power: 5.5 kW

weight: 260 kg

self-cleaning

rotation speed: 7600 rev/min

motor power: 15 kW

weight: 800 kg

self-cleaning

rotation speed: 5800 rev/min

motor power: 22 kW

weight: 1850 kg

self-cleaning

rotation speed: 4700 rev/min

motor power: 37–45 kW

weight: 2300 kg

self-cleaning

rotation speed: 4800 rev/min

motor power: 30 kW

weight: 2300 kg

self-cleaning

rotation speed: 5300 rev/min

motor power: 30 kW

weight: 2400 kg

with manual sludge discharge

rotation speed: 6700 rev/ min

motor power: 11–15 kW

weight: 750 kg

with manual sludge discharge

rotation speed: 4700 rev/min

motor power: 18.5 kW

weight: 2300 kg

with manual sludge discharge

rotation speed: 4700 rev/min

motor power: 22 kW

weight: 2300 kg

with manual sludge discharge

rotation speed: 9600 rev/min

motor power: 2.2 kW

weight: 145 kg

with manual sludge discharge

rotation speed: 9500 rev/min

motor power: 0.55 kW

weight: 90 kg

with manual sludge discharge

rotation speed: 9600 rev/min

motor power: 1.5 kW

weight: 65 kg

with manual sludge discharge

rotation speed: 7800 rev/min

motor power: 5.5 kW

weight: 260 kg

Category description

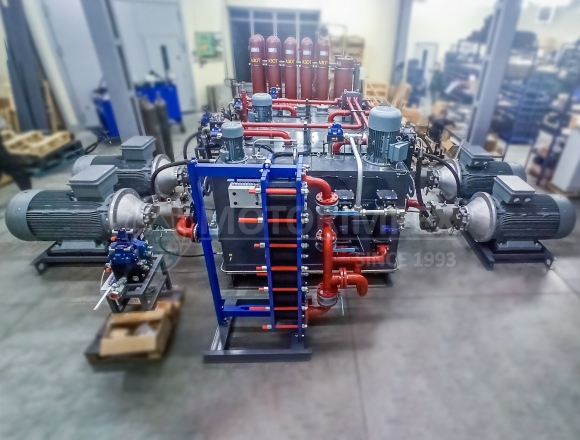

Working fluid cleaning systems

Application of working liquid cleaning systems

Centrifuges for cleaning can be used for oils cleaning in engines or in static equipment, also for part regeneration of used oils. Centrifugal force is used to separate solids from liquids and for water separating.

Centrifuge device:

- body with lid;

- rotor, which is installed in the housing on two bearings and is equipped with hydro-jet nozzles and a column with a channel for supplying the purified liquid to the nozzles.

The bearing housings have an elastic support of low rigidity, which allows their lateral displacements. The rotor is also equipped with a flexible branch pipe for partial drainage of the cleaned liquid. Hydraulic centrifuges are one of the most efficient centrifugal liquid cleaners. They are divided into partially threaded and full-threaded. Both those and others may have a different performance. There are centrifuges with rotors mounted on a solid axis with high resistance to rotation, as a result of which the rotational speed of the rotors is low.

The range of hydraulic equipment of the Motorimpex company includes liquid purification systems operating on the separation principle from the manufacturer Macfuge:

Macfuge fluid purification systems are characterized by reliability and high quality in accordance with ISO 9001: 2008 standards.

pulling force: 6.8 t

flow rate: 60 l/min

working pressure: 155 bar

rope: 25 m x Ø 12 mm

pulling force: 4.5 t

motor displacement: 50 cm3/rev

flow rate: 5 - 45 l/min

rope: 25 m x Ø 10 mm

maximum torque: 2500 N∙m

maximum speed: 900 rpm

maximum power: 22 kW

maximum displacement: 398 cm3/rev

maximum working pressure: 450 bar

maximum torque: 4770 N∙m

maximum speed: 700 rpm

maximum power: 50 kW

maximum displacement: 750 cm3/rev

maximum working pressure: 450 bar

maximum working pressure: 290 bar

maximum displacement: 122.72 cm3/rev

maximum working pressure: 400 bar

maximum displacement of section: 75.1 cm3/rev

DN 6, 10

maximum working pressure: 315 bar

maximum flow rate: 180 l/min

capacity: 0.075–4 l

maximum working pressure: 350 bar

G3/8

maximum working pressure: 350 bar

G1/8, М5х0,8, G1/4, G3/8, G1/2

scheme: 5/2, 5/3

max. number of cycles per sec.: 5

response time: 0,05 sec