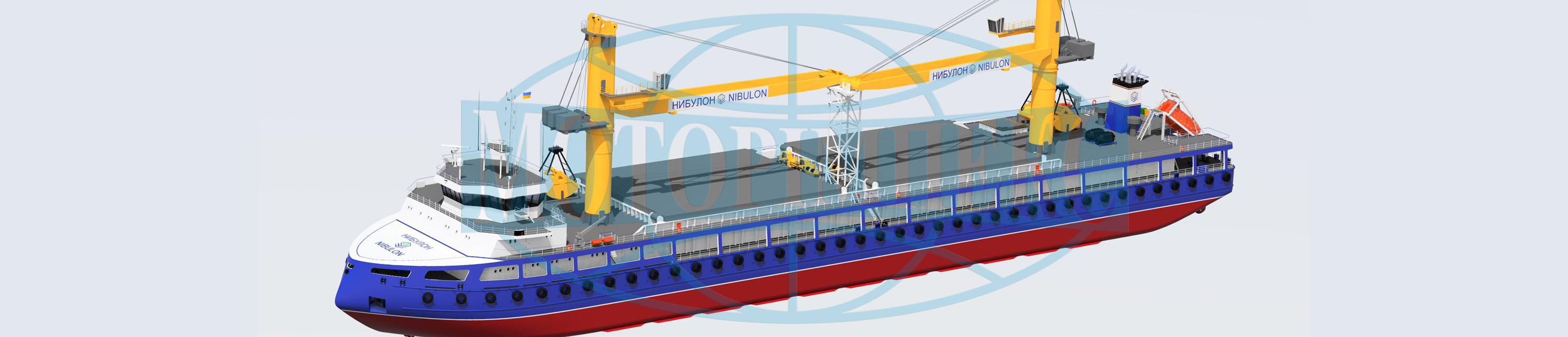

Turnkey hydraulics – hydraulic drive for boat hatches for the "Nibulon Max" ship

The hydraulic system of the self-propelled reloader consists of two hydraulic power units МІ-1130 with control panels, four hydraulic cylinders and pipe wiring. It performs the function of opening and closing the hold hatch of the "Nibulon Max" vessel.

Nominal pressure: 320 bar;

Hydraulic tank capacity: 32 cc/rev;

Oil tank hydraulic tank capacity: 600 l;

Power of electric motors: 30 kW.

During the project, all parts of the Motorimpex group of companies were involved:

– calculations and design – design bureau;

– component supply – trade company;

– production of hydraulic stations with control systems and hydraulic cylinders, their testing – Production Enterprise;

– installation and connection of hydraulic equipment on a ship,

– installation of pipe wiring (1 km),

– connection of control panels,

– flushing and commissioning – customer service.

Hydraulic power units of type MI are certified, meet the requirements of DSTU EN ISO 4413:2014.

The management system of the Motorimpex group of companies meets the requirements of ISO 9001:2015

37 business days passed from the moment we received the request until its implementation by the technical control department of the Nibulon shipbuilding and ship repair plant. The project was completed in the required time – before the start of the exhibition “Shipbuilding and Water Transport-2019”, where everyone could see our hydraulic system on board the “Nibulon Max”.

Principle of action

For a consistent rise of bilge hatches, the controls include voltage feed to the electric motor of hydraulic power units.

The launch of motor-pump units groups takes place from electric motor with light start. Hydraulic pumps are in "unloading" mode until the time of moving the directional control valve grip into the position of "pushing out/retraction" hydrocylinder.

To raise a bilge hatch, the handle of the directional control valve is transferred to the "pushing out" mode of cylinder. The pump goes from the "unloading" mode to “pressure feed" mode – there is a pushing of hydrocylinder.

When raising the hydrocylinder of the final position, its sensor delivers a light and sound signal to remote control (up to 30 sec duration). The light and sound signals only work in case both end position sensors locked up. Cylinders are under pressure until the operator lets go of the control handle and it will return to "unloading" mode with a springs return.

Excessive pressure in the system is limited to the setting of the relief valve. The brake valve holds hydrocylinder in a static position under pressure until the time of the inclusion of the "retraction". The speed of raising hatch is adjustable using throttle valve. Hatch pickup time at a fully open throttle valve is 272 seconds.

To lower the bilge hatch, the handle of the directional control valve is transferred to the "retruction" mode of hydraulic cylinders. Hydraulic pump goes from "unloading" mode into “pressure feed" mode – the retruction of hydraulic cylinders is happening.

We develop and implement turnkey projects since 2010.

For consulting from hydraulic engineers and filling out requests for calculation and production of hydraulic drives for your projects, call or message us.